TM 55-607/NAVSEA OP 3221 Rev 2

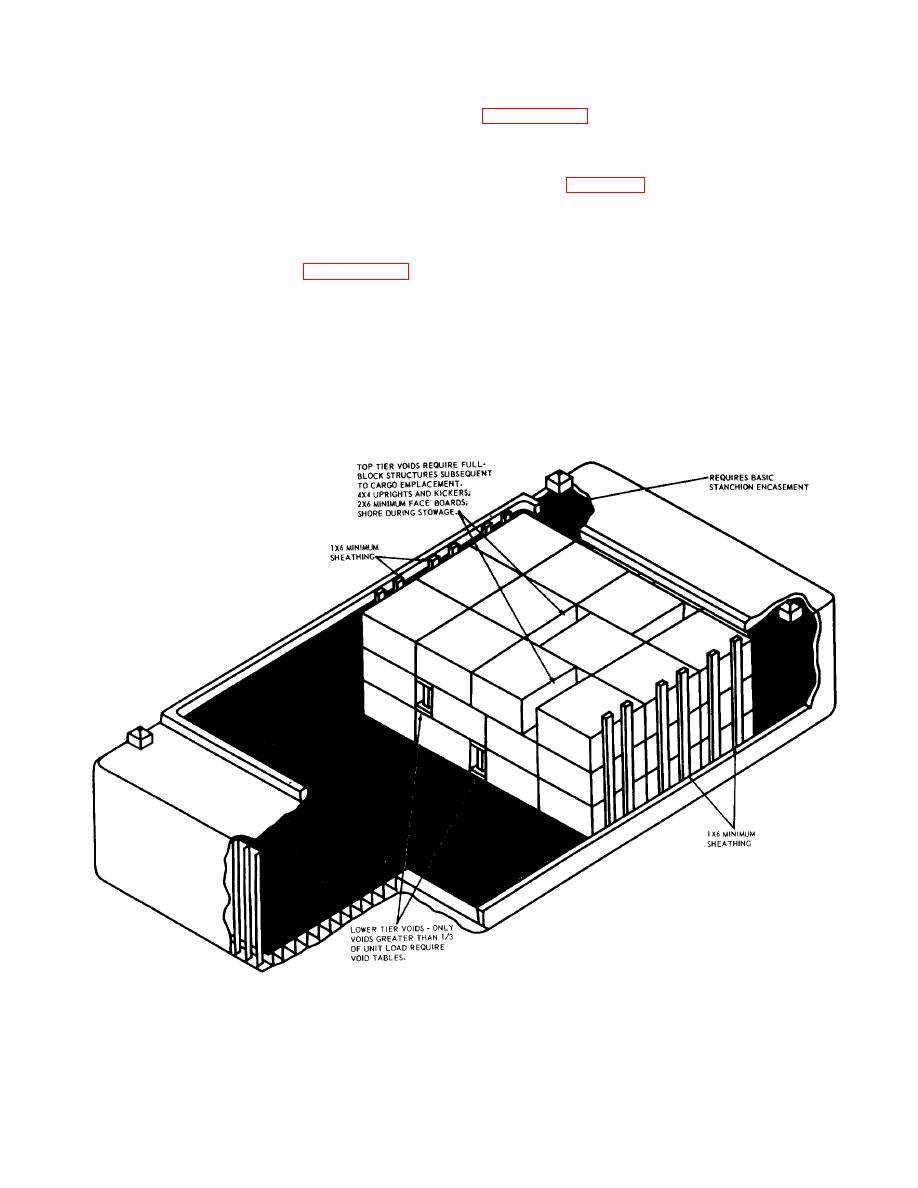

(3) Modified block stow. It was noted previously in paragraph 9-4 that when the hull angles approach the

perpendicular, then over-stowed unit loads are no longer offset and the sweatboard-to-sweatboard technique resembles

block stowage. However, since the voids in the center of the stow can still be shored in accordance with the sweatboard-

to-sweatboard technique, the final stowage technique to be described can be referred to as a "modified" block-stowage

pattern. Utilization of this stowage pattern in a LASH lighter is illustrated in figure 10-9. As with conventional block stow,

stowage operations begin at both ends of the barge with cargo being placed tight against sheathing and basic

encasement structures. Voids that occur in the center of the stow are staggered between tiers so that they do not occur

directly over each other. Voids in the lower tiers less than one-third the width of a TM 55-607/NAVSEA OP 3221 Rev 2

unit load do not require shoring. Large voids require vertical support, and a void table must be used. Detailed void-

shoring techniques are discussed in paragraph 8-5. Only voids in the top tier require full-block structures. Unlike the

conventional sweatboard-to-sweatboard stowage technique, tier stripping is not normally required, since palletized unit

loads are not offset and voids never occur under two unit loads. Skidded unit loads or items palletized on metal adapters

may require tier stripping for adequate support. The modified block-stowage pattern eliminates the need for large full-

block structures; only basic encasement shoring, void tables, and top-tier block structures are required, and all may be

prefabricated. On stows where the center voids are less than one-third the size of the unit load, void tables are not

required.

Figure 10-9. The modified block-stowage pattern.

10-11