TM 5-2420-231-23-1

0086

PUMP OUTPUT TEST CONTINUED

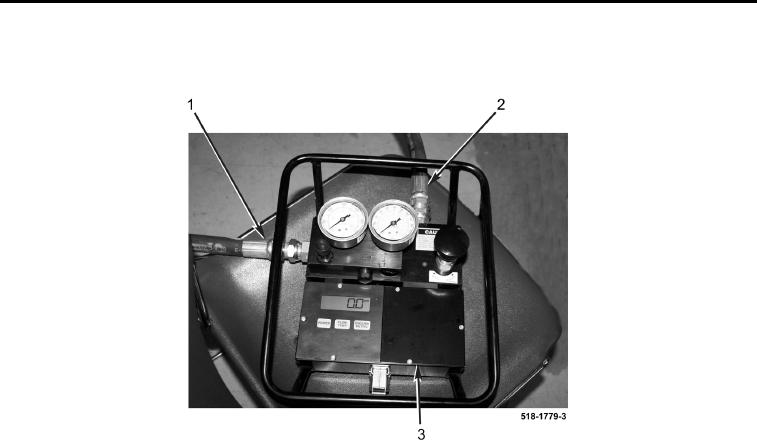

5. Connect inlet hose (Figure 60, Item 1) and outlet hose (Figure 60, Item 2) to flowmeter (Figure 60, Item 3).

Figure 60. Flowmeter Connections.

0086

6. Completely open load valve (Figure 61, Item 2) on flowmeter (Figure 61, Item 3) by rotating counterclockwise.

7. Start and run engine until oil is at operating temperature (TM 5-2420-231-10). If oil is not at operating

temperature, perform the following:

a. Close load valve (Figure 61, Item 2) on flowmeter (Figure 61, Item 3) until pressure gauge (Figure 61,

Item 1) indicates 1,000 psi (6,895 kPa).

b. Run engine at full throttle until temperature is 125F (52C).

8. Press POWER button (Figure 61, Item 5) to activate flow gauge (Figure 61, Item 4).

9. Run engine at 2,000 rpm and record flow reading from flow gauge (Figure 61, Item 4).

10. Extend dipper (TM 5-2420-231-10) and hold in deadhead position.

11. Slowly close load valve (Figure 61, Item 2) until pressure gauge (Figure 61, Item 1) reads 2,000 psi (13,789

kPa). Record flow reading from flow gauge (Figure 61, Item 4).

12. Decrease engine speed to low idle and stop engine (TM 5-2420-231-10).

13. Divide flow reading at 2,000 psi (13,789 kPa) by the flow reading obtained in step 9. Multiply this answer by

100 to obtain percent efficiency of pump. If efficiency is less than 70 percent, replace pump. If efficiency of

pump is at least 70 percent, the pump is good.