TM 5-3805-255-14

0068

ADJUSTMENT CONTINUED

00068

4. If indicated pull does not lie between given limits, make the following adjustments:

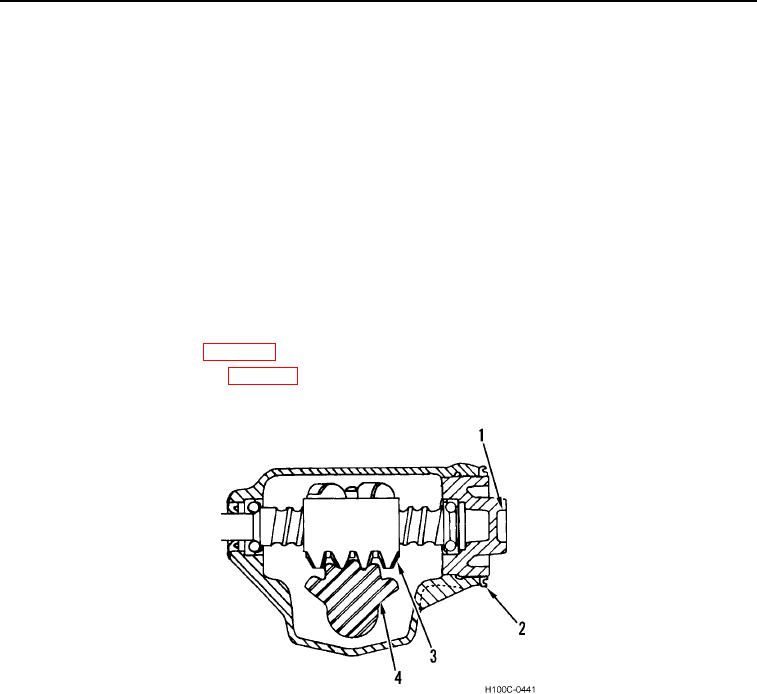

a. Loosen locknut (Figure 5, Item 2).

b. Turn adjuster (Figure 5, Item 1) until required resistance to pull (1.5 to 5.5 lb-in. [0.169 to 0.621 Nm)] is

reached.

c.

Tighten locknut (Figure 5, Item 2) to 18 to 27 lb-ft (24 to 37 Nm) torque and recheck pull. Pull resistance

must lie between limits specified after locknut is tightened.

d. Turn lash adjuster screw (Figure 5, Item 1) clockwise to remove lash from ball nut (Figure 5, Item 4) gear

teeth and pitman shaft (Figure 5, Item 3) gear teeth. Tighten locknut (Figure 5, Item 2).

e. Check pull with socket and lb-in. torque wrench as before, taking highest reading of scare as shaft is

turned through center position. This should be 3.0 to 7.0 lb-in. (0.339 to 0.790 Nm) over bearing adjust-

ment but not to exceed a total of 11.0 lb-in. (1.24 Nm).

f.

Readjust lash adjuster screw (Figure 5, Item 1) if necessary to obtain proper pull. Tighten locknut (Figure

5, Item 2) to 18 to 27 lb-ft (24 to 37 Nm) torque and recheck pull. Pull resistance must lie between specified

limits after locknut is tightened.

5. Install body access panels (WP 0005).

6. Install drag link to pitman arm (WP 0072).

Figure 5. Gear Lash Final Adjustment.

068

END OF TASK

END OF WORK PACKAGE

0068-4