If stall rpm is not within specifications, trouble

shooting of engine or torque converter by a quali-

fied mechanic is required. See Specifications and

Service Data.

Note: Stall rpm specified in Specifications and

Service Data at rear of this manual is applicable

to altitude of 600 ft. and ambient temperature of

7 0 F . Do to many combinations of altitude and

temperature possible in the field, space does not

p e r m i t publishing here all the corrections neces-

s a r y to the stall rpm indicated to accommodate

such variations. It is suggested the engine manu-

f a c t u r e r ' s distributor be contacted to determine

the correction necessary for altitude and tempera-

ture in your application.

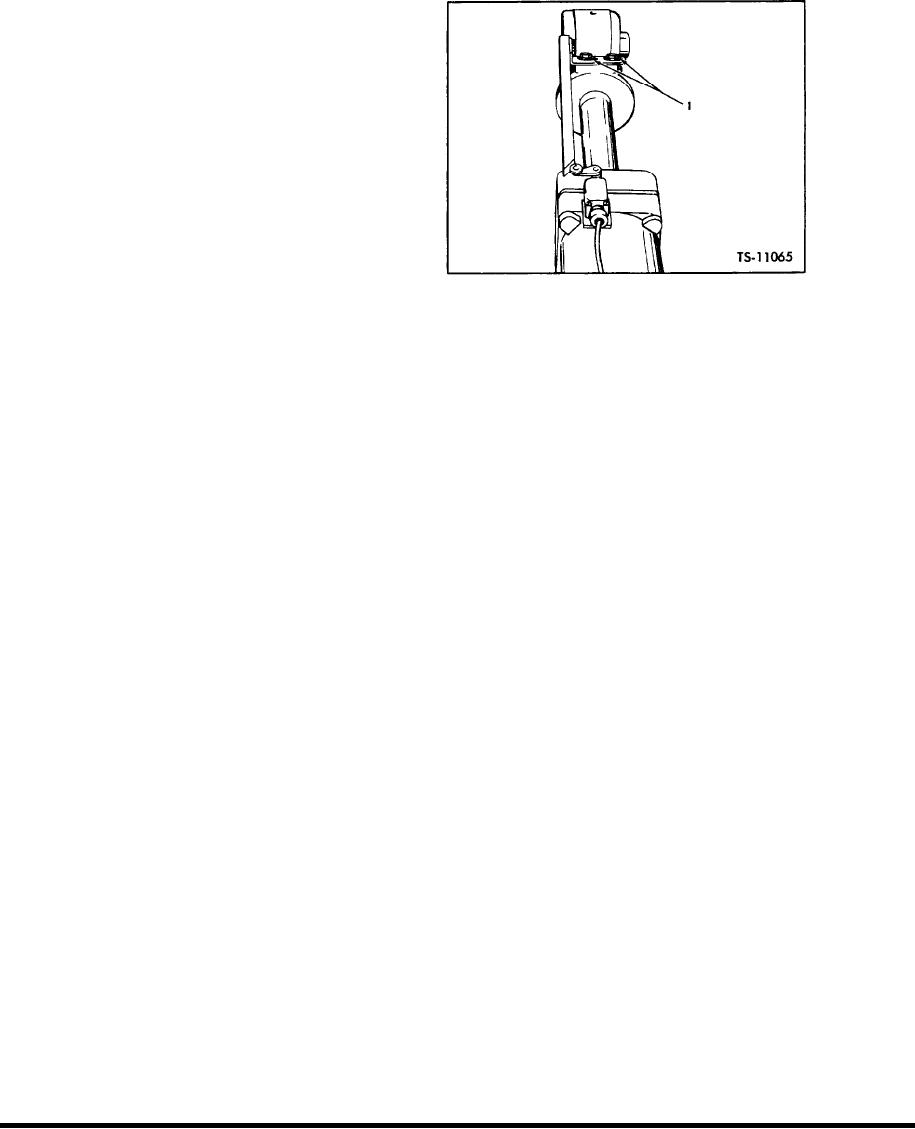

Adjust Bucket Leveler

Fig. 16.

Adjust Bucket Leveler: The bucket leveler

bucket is in a level position.

mechanism consists of a leveler cam and an electric

4. Additional adjustment is provided at the roller

switch mounted on the right hand bucket cylinder,

arm on the electric switch. Maximum stroke of

a n d a solenoid operated air valve. The electric

roller arm is 9/16 inch.

switch is wired to the solenoid operated air valve,

which in turn is connected to the air tank and main

5. Start engine. Raise bucket to a number of dif-

hydraulic valve by piping.

ferent heights and cycle bucket slowly at each

of these various heights to check proper opera-

The roller arm on the electric switch rolls off

tion. Each time bucket is rotated back from the

the leveler cam as the bucket is rotated back from

D U M P position, the bucket lever should return

the DUMP position. This action closes the electric

automatically to the HOLD (neutral) position.

switch and completes the circuit, sending a flow of

electricity to the solenoid operated air valve. This

releases a flow of air from the tank to the main

Adjust Boom Kickout: The boom kickout mech-

control valve causing the bucket lever to move from

anism consists of a boom cylinder mounted kickout

the detent located CLOSE position to the HOLD (neu-

cam, a frame mounted electric switch and solenoid

tral) position. The bucket will then stop in a level

mounted at the control valve boom spool.

position.

To obtain maximum height kickout switch

S e r v i c i n g and adjustment procedures are as

bracket should be installed in bottom slots of frame

follows : Refer to Figure 16 for correct position of

bracket. The roller on the electric switch should

leveler cam in relation to roller on electric switch

j u s t contact cylinder mounted kickout cam. This

when bucket is in a level position.

will cause boom kickout to occur at approximately

1 foot (30,5 cm) from maximum height. Lower

Caution: Leveler cam must be parallel to bucket

boom kickout positions may be obtained by raising

cylinder rod at all times.

switch bracket in mounting slots.

1. Start engine, position bucket level on ground,

Bleed Brake System: Occasionally it may be

shut down engine and pull bucket lever into de-

n e c e s s a r y to bleed brake system to remove air

tent located CLOSE position.

trapped in the system due to a leak in the line or

t h e installation of new parts in the system. Air

2. Adjustment is provided at the leveler cam

trapped in the system will be indicated by a soft

bracket. Elongated holes in the leveler cam

spongy brake pedal.

b r a c k e t allow adjustment either in or out to

m a i n t a i n proper roller arm stroke, l/8 inch to

Note: It is recommended to use a bleeder hose

actuate. (Figure 16 Item 1).

on bleeder values whenever possible to keep fluid

3. The roller on the electric switch should be just

a w a y from linings. Keep master cylinder(s) filled

off, but nearly touching the leveler cam when

during bleeding process.

[45-04-2]