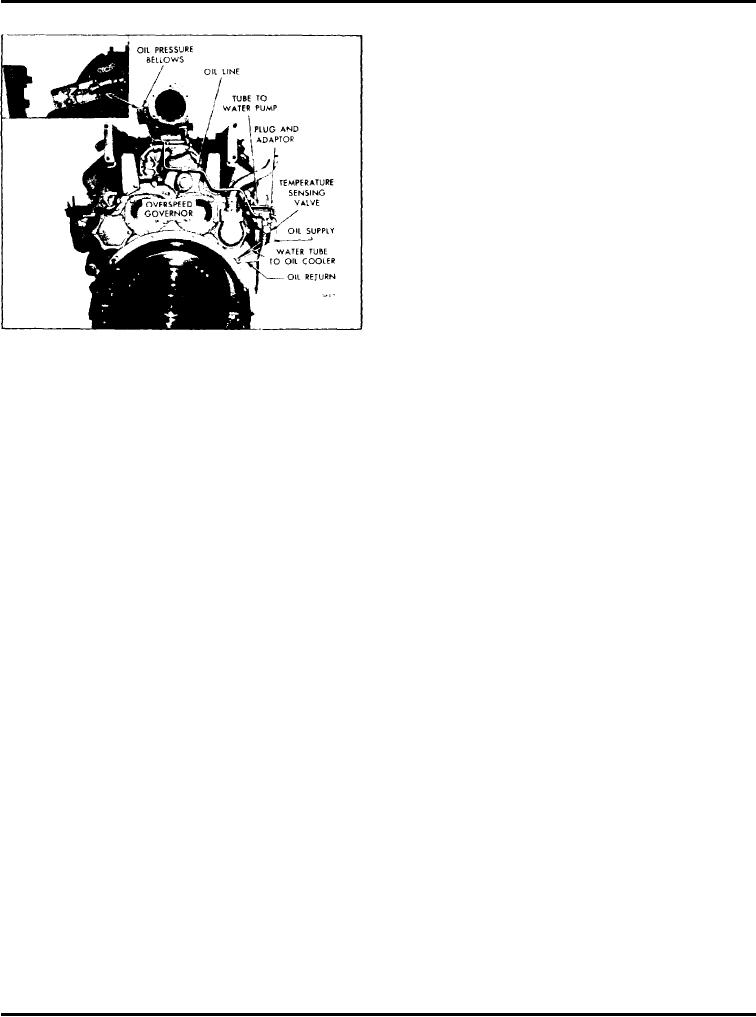

Engine Equipment

If the engine coolant overheats, the temperature-

sensing valve will open and permit the oil in the

protective system to flow to the engine crankcase.

The resulting decrease in oil pressure will actuate the

shutdown mechanism and stop the engine. Also if the

engine loses its coolant, the copper plug will be heated

up by the hot exhaust gases passing over it and cause

the temperature-sensing valve to open and actuate the

shutdown mechanism.

Whenever the engine speed exceeds the overspeed

governor setting, the oil in the line flows to the sump,

resulting in a decrease in oil pressure. The oil pressure

bellows then releases the latch and permits the air

shut-off valve to close.

When an engine is stopped by the action of the

shutdown system, the engine cannot be started again

until the particular device which actuated the

Fig. 3 - Automatic Mechanical Shutdown

shutdown mechanism has returned to its normal

System Mounting

position. The abnormal condition which caused the

engine to stop must be corrected before attempting to

The overspeed governor (Fig. 4), used on certain

start it again.

applications, consists of a valve actuated by a set of

spring-loaded weights. Engine oil is supplied to the

valve through a connection in the oil line between the

bellows and the temperature-sensing valve. An outlet

Adjustment

in the governor valve is connected to the engine oil

The only adjustments necessary in the mechanical

sump. Whenever the engine speed exceeds the

shutdown system are the low oil pressure setting of the

overspeed governor setting, the valve (actuated by the

bellows and the overspeed setting of the overspeed

governor weights) is moved from its seat and permits

governor or overspeed valve assembly. Replace the

the oil to flow to the engine sump. This decreases the

t e m p e r a t u r e sensing valve when operation is

oil pressure to the bellows, thus actuating the shutdown

unsatisfactory.

mechanism and stopping the engine.

To adjust the low oil pressure setting of the bellows,

A restricted fitting, which will permit a drop in oil

start. and run the engine until the normal operating

pressure great enough to actuate the shutdown

temperature (160-185 F or 71-85C) has been

mechanism, is required in the oil line between the

reached and the oil pressure has stabilized. Then

cylinder block oil gallery and the shutdown sensing

reduce the engine speed slowly until the bellows

devices.

disengages the latch on the air shut off valve and stops

the engine. Note the oil pressure at which the shut

down occurred. The oil pressure at disengagement

Operation

should be 5-10 psi (35-69 kPa) at 450-600 rpm; 10-

15 psi (69-103 kPa) at 601-1400 rpm; or 15-20 psi

To start an engine equipped with a mechanical

(103-138 kPa) at 1401 and above rpm. If adjustment is

shutdown system, first manually open the air shut-off

necessary, loosen the lock nut on the bellows and turn

valve and then press the engine starting switch. As

the adjusting screw clockwise to increase the oil

soon as the engine starts, the starting switch may be

pressure setting or counterclockwise to decrease the

released, but the air shut-off valve must be held in the

setting. Hold the adjusting screw and tighten the lock

open position until the engine oil pressure increases

nut when the proper setting has been obtained.

sufficiently to permit the bellows to retain the latch in

the open position.

NOTE: Set the bellows disengagement pressure

as near as possible to the high end of the

pressure range for the low engine speed

During operation, if the engine oil pressure drops

specified for the engine. For an engine

below the setting of the pressure sensitive bellows, the

equipped with a dual speed governor, set the

spring within the bellows will release the latch and

permit the air shut-off valve to close, thus stopping the

bellows disengagement at the lower setting of

the engine governor.

engine.

Page 33