Engine Equipment

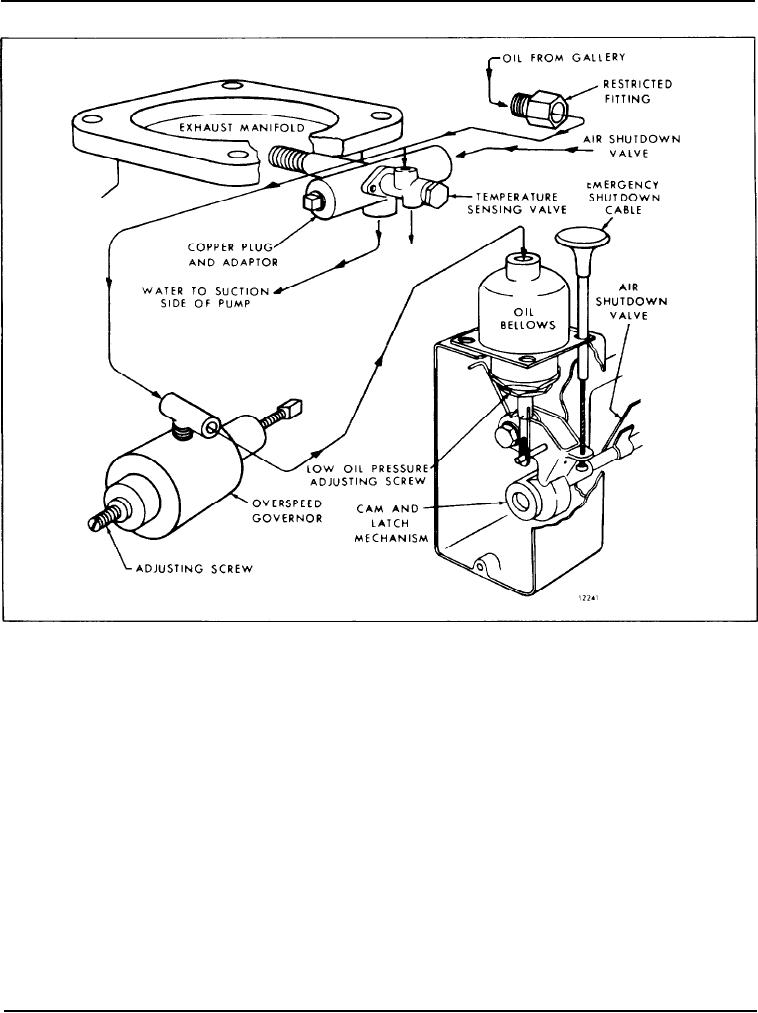

Fig. 4 - Schematic Drawing of Automatic Mechanical Shutdown System with Overspeed Governor

Check the operation of the engine coolant tempera-

attaching an air hose (40 psi or 276 kPa air supply) to

ture-sensing valve by placing a cover over the radiator

the oil inlet side and installing a tube from the outlet

while the engine is operating at part load and note the

side to a can of water. Then immerse the power

coolant outlet temperature at which the bellows

element of the valve in a container of water that is

disengages the air shutdown latch. The air shut-off

heated and agitated. Check the temperature of the

valve should close and stop the engine within a

water with a thermometer. Apply air to the valve. The

temperature range of 200-210 F (93-99 C). If the

valve should be open, as indicated by the flow of air.

engine is not shut down in this range, replace the

at a water temperature of 195-206 F (91-95 C).

temperature-sensing valve. If the engine is shut down

below 200 F (93 C), check the coolant flow through

To adjust the overspeed governor, start and run the

the plug and adaptor assembly and, if circulation is

engine until normal operating temperature is reached.

satisfactory, replace the temperature-sensing valve.

Then increase the engine speed to the desired

overspeed shutdown speed. At this speed, the bellows

NOTE: If a premature engine shutdown occurs,

should disengage the air shutdown latch and stop the

check the copper plug. A spring and plunger

engine. If necessary, adjust the overspeed governor

assembly are used with the current type plug to

setting by loosening the lock nut on the adjusting

provide an unobstructed flow of coolant over

the temperature-sensing valve element.

screw at the rear of the governor and turn the screw

clockwise to increase the shutdown speed or counter-

The temperature-sensing valve can be bench tested by

clockwise to decrease the shutdown speed. Then

Page 34