Engine Systems

The radiator is reverse-flushed as follows:

1. Remove the radiator inlet and outlet hoses and

replace the radiator cap.

2. Attach a hose at the top of the radiator to lead

water away from the engine.

3. Attach a hose to the bottom of the radiator and

insert a flushing gun in the hose.

4. Connect the water hose of the gun to the water

outlet and the air hose to the compressed air outlet.

5. Turn on the water and, when the radiator is full,

turn on the air in short blasts, allowing the radiator to

fill between air blasts.

CAUTION: Apply air gradually. Do not exert

more than 30 psi (207 kPa) air pressure. Too

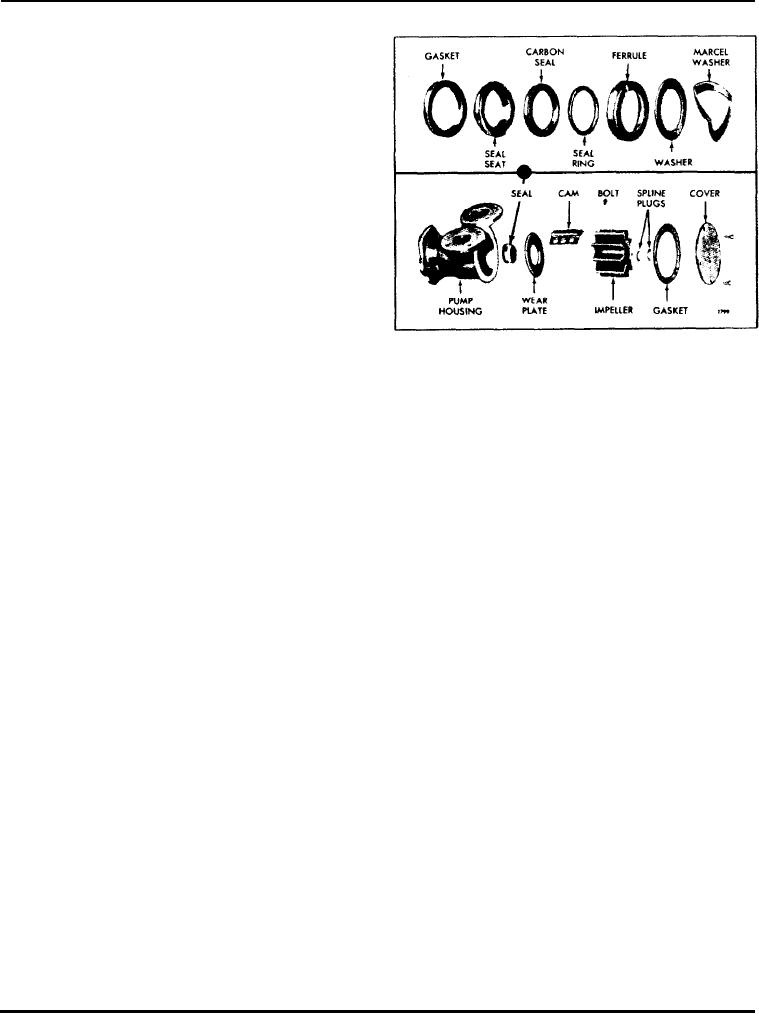

Fig. 20 - Raw Water Pump Details and

great a pressure may rupture a radiator tube.

Relative Location of Parts

6. Continue flushing until only clean water is expelled

When water connection seals and hoses are installed,

from the radiator.

be sure the connecting parts are properly aligned and

the seal or hose is in its proper position before

The cylinder block and cylinder head water passages

tightening the clamps. All external leaks should be

are reverse-flushed as follows:

corrected as soon as detected.

1. Remove the thermostat and the water pump.

The fan belt must be checked and adjusted, if

2. Attach a hose to the water inlet of the cylinder block

necessary, to provide the proper tension and the fan

to drain the water away from the engine.

shroud must be tight against the radiator core to

prevent re-circulation of air which may lower the

3. Attach a hose to the water outlet at the top of the

cooling efficiency.

cylinder block and insert the flushing gun in the hose.

4. Turn on the water and, when the water jackets are

filled. turn on the air in short blasts, allowing the

Water Pump

engine to fill with water between air blasts.

The centrifugal type water pump is mounted on the

5. Continue flushing until the water from the engine

runs clean.

engine front cover and is driven by a front camshaft

gear. This pump circulates the engine coolant through

If scale deposits in the radiator cannot be removed by

the cylinder block, cylinder head, heat exchanger or

chemical cleaners or reverse-flushing as outlined

radiator and the oil cooler.

above, it may be necessary to remove the upper tank

and rod out the individual radiator tubes with flat steel

The pump consists of a bronze impeller secured to a

rods. Circulate water through the radiator core from

stainless steel shaft with a lock nut. A gear is pressed

the bottom to the top during this operation.

on the opposite end of the shaft and the shaft turns on

two ball bearings. An oil seal is used ahead of the

front bearing and a spring-loaded face type water seal

Miscellaneous Cooling System Checks

is used in back of the impeller. The pump ball

In addition to the above cleaning procedures, the other

bearings are lubricated with oil splashed by the water

components of the cooling system should be checked

pump gear.

periodically to keep the engine operating at peak

efficiency. The cooling system hoses, thermostats and

Contact an authorized Detroit Diesel Allison Service

radiator pressure cap should be checked and replaced

Outlet if more information is needed.

if found to be defective.

Page 29