Engine Equipment

2. Pull out the "Quick Start" knob for two seconds,

then release it.

3. Repeat the procedure if the engine does not start on

the first attempt.

CAUTION: Do not crank the engine more than

30 seconds at a time when using an electric

starting motor. Always allow one minute

intervals between cranking attempts to allow

the starting motor to cool.

Service

Periodically perform the following service items to

assure good performance:

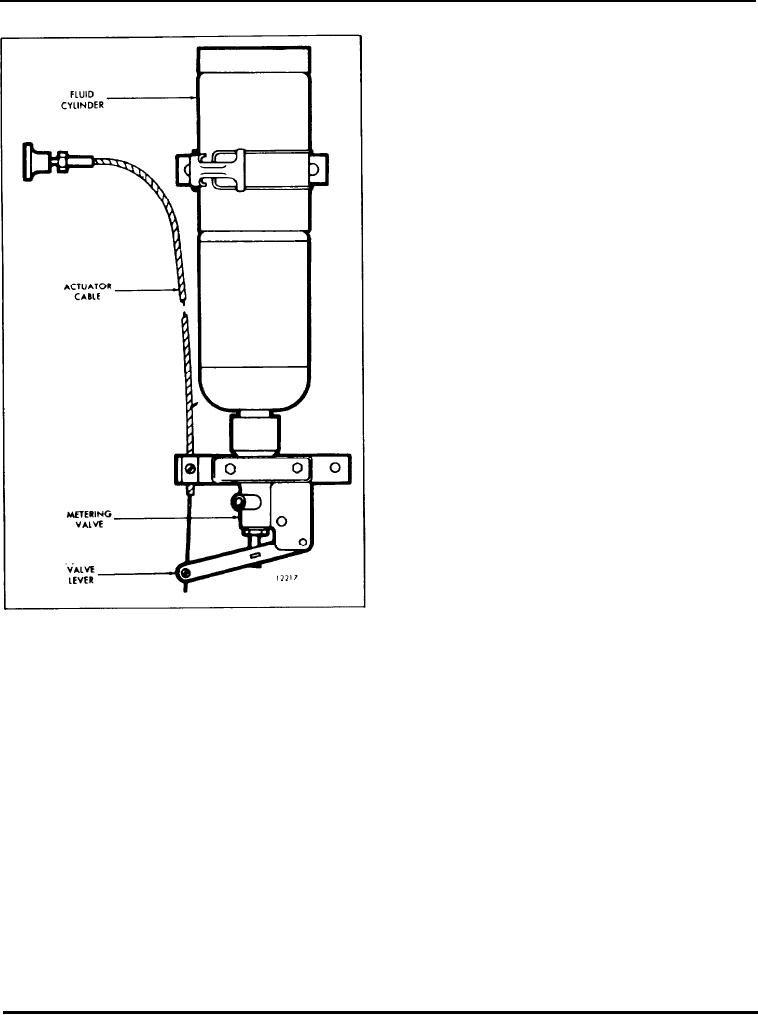

1. Remove the fluid cylinder and lubricate the valve

around the pusher pin under the gasket with a few

drops of oil.

2. Lubricate the actuator cable.

3. Actuate the valve with the cable to distribute the oil

on the cable and allow the oil to run down through the

valve.

4. Remove any dirt from the orifice by removing the

air inlet housing fitting, the orifice block and the

screen. Then blow air through the orifice end only.

5. Assemble and tighten the air inlet housing fitting to

the actuator valve and tube.

6. Check for leakage of fluid (fogging) on the outside

of the engine air inlet housing by actuating the

starting aid while the engine is stopped. If fogging

Fig. 12 - Quick Start Assembly

occurs, disassemble and retighten the air inlet housing

fitting to the housing.

PRESSURIZED CYLINDER STARTING AID

CAUTION: Do not actuate the starting aid more

Start the engine during cold weather, using the "Quick

than once with the engine stopped. Over-

Start" starting aid system (Fig. 12) as follows:

loading the engine air box with this high volatile

fluid could result in a minor explosion.

1. Press the engine starter button.

7. Check the fluid cylinder for hand tightness.

Page 45