Engine Equipment

down when the engine is stopped. This drop lets the

(approximately 500 rpm) with the clutch disengaged.

ridge locate between the pressure plates. The drive

The speed will he sufficient to move the segments out

ring cannot he properly adjusted to the recommended

to operating position.

engaging pressure with the disc so positioned. The

2. Check the pounds pressure required to engage the

condition can result in excessive slippage and a need

clutch. The engagement pressure should be the same

for early clutch facing replacement.

as that following the adjustment. If the clutch engages

at a lower pressure, the adjustment was probably made

Make a final clutch adjustment check with the engine

against the unworn portion of the facing.

running, to make sure the adjustment was not made

against the ridge. The procedure is outlined below:

3. Stop the engine and readjust the clutch, making sure

all disc segments are properly positioned. Install the

1. Start the engine and operate it at idling speed

inspection hole cover.

TORQMATIC MARINE GEAR

The Torqmatic marine gear is used on 6V and 8V

110-150 psi (758-1034 kPa) in reverse. The average

single engine marine units and tandem twin marine

operating oil temperature is 200 F (93 C) in forward

units. The marine gear consists of a reverse gear

and a maximum of 250 F (121 C) in reverse.

section and a reduction gear section. Each marine gear

is available in several gear ratios.

A strainer is used between the oil sump and the pump

to remove harmful solids. The oil passes from the

pump through a cooler to the control valve. From the

The oil for operating the hydraulic clutches and for

control valve, the oil operates the forward or reverse

lubricating the reverse gear is contained in the reverse

clutch pistons and sprays oil into the reduction gear

gear sump and is circulated throughout the system by

housing to lubricate the gear.

a hydraulic oil pump mounted on the flywheel housing

and driven from the blower drive shaft through a

The constant flow control valve, incorporated with a

flexible coupling.

pressure relief valve, controls the amount of oil

pumped through the hydraulic system and is sensitive

The oil pressure ranges for the marine gear at forward

only to engine speed and operates independently of

operating speed are 130-155 psi (896-1068 kPa) and

the pressure relief valve section which controls the

pressure within the complete hydraulic system.

When the engine is in operation, the moving parts of

the marine reverse gear are pressure lubricated while

the reduction gear assembly is splash lubricated.

Shifting from forward to reverse drive through neutral

may he made at any speed; however, it is advisable to

shift at low engine speeds. For longest clutch life,

reduce the engine speed to idle, make the shift and

then increase the engine speed.

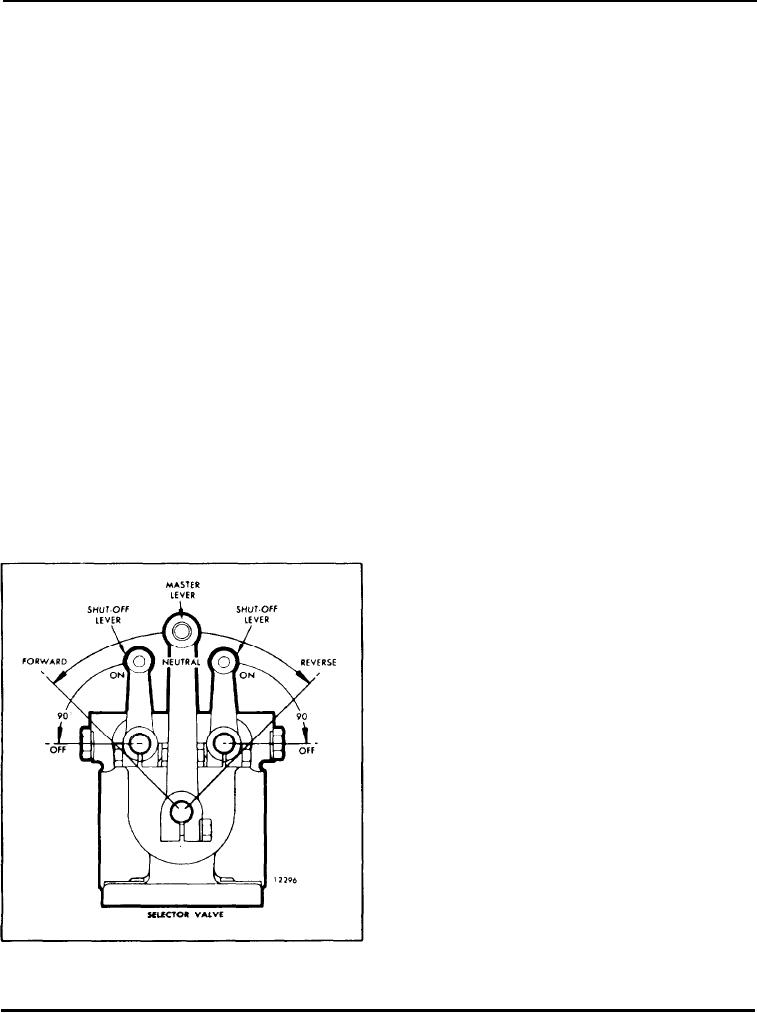

The marine gear selector control valve assembly on the

tandem twin marine engine unit is provided with

several levers (Fig. 17). The master control lever

engages both marine gears in forward or reverse

simultaneously. The smaller levers, one for each

engine, operate the shut-off control valves for

controlling the flow of oil to each individual engine

marine gear. These levers are normally set in a vertical

position ("on" position). To shutdown one engine for

service work or to conserve on power in a light load

situation, place the master control lever in the neutral

position and then turn the shut-off lever for that

engine to the "off" position (90 degrees toward the

Fig. 17 - Lever Arrangement on Tandem Twin

engine). With the shut-off lever in the "off' position,

Engine Marine Gear Selector Valve

the marine gear for that engine is locked out of

Page 49