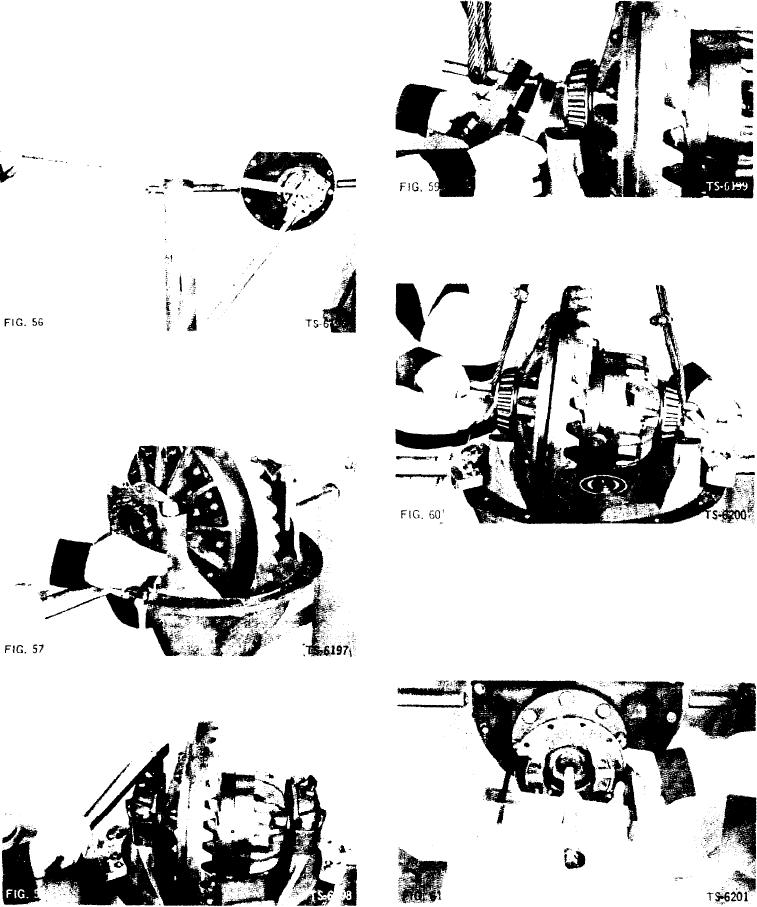

5. Insert metal bar through differential to facilitate hoist-

2. If axle is not equipped with parking brake, companion

ing. Raise ends individually and remove adjusting nuts

flange nut should be loosened now to facilitate flange

and bearing cups (Fig. 59).

removal later. Position socket on flange nut and then

install flange retainer tool with two spacers between

tool and flange. Spacer dimensions are given in fig. 30.

Loosen flange nut [Fig. 56).

NOTE: Standard 2 5/8 -inch socket will not fit flange nut

because socket walls are too thick to enter flange.

Machine socket as shown in Fig. 31 to provide proper

clearance.

6. Hoist differential with assembled bearing cones from

carrier assembly (Fig. 60). Tilt differential to allow ring

gear to pass web in differential carrier.

3. Remove lockwire and adjusting nut lock. Before remov-

ing bearing cap bolts, use center punch to matchmark

bearing caps to carrier assembly. This is to insure cor-

rect match in reassembly (Fig. 57).

7. If axle is not equipped with parking brake, remove

shaft nut that was loosened as shown in Fig. 56. Re-

move washer. Remove companion flange from pinion

shaft with puller (Fig. 61). If companion flange was

removed to provide access to parking brake and re-

installed to facilitate handling differential, it can prob-

ably be removed by hand.

4. Remove bearing cap bolts and bearing caps (Fig. 58).

[25]