26. Install inner spindle nut on spindle. Wrap several

24. Lubricate lip of hub and drum oil seal with Lubri-

turns of .010 inch to .020 inch shim stock around

plate. Position hub and drum on axle (Fig. 179). Care

splines of axle shaft to protect splines. Install spindle

should be taken to align hub and drum assembly

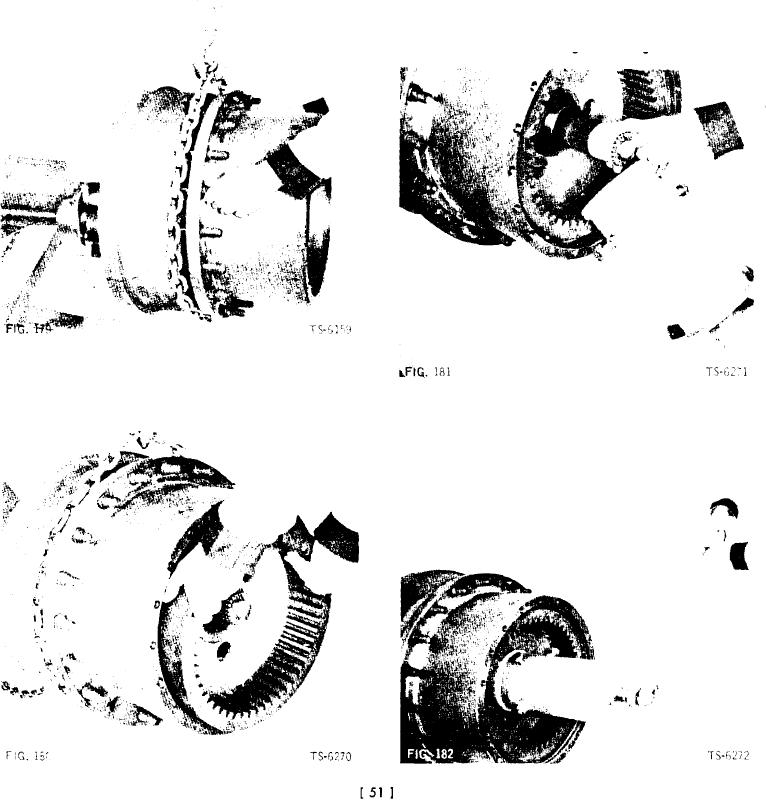

nut socket wrench, Part No. 945940, on nut (Fig.

with spindle so that no cocking of inner hub bearing

181) and tighten guide bolts lightly against axle

occurs when sliding assembly on spindle. If difficulty

shaft.

is encountered when trying to position the brake

drum over the brake shoes, check for improper ad-

NOTE: The tapered roller bearings utilized in wheel

justment of slack adjuster. During installation, slack

hub must be preloaded in accordance with procedure

adjusters must be adjusted to minimize brake spring

steps and specifications given below. One of two

tension.

methods may be used in adjusting the required pre-

load on these bearings. It should be noted that pre-

load specifications differ for use of new bearings

and when wheel bearings are being reused.

25. Continue to support hub and drum with hoist. Position

internal gear and hub on axle so that it engages

splines on spindle (Fig. 180).

F i r s t (Preferred) Method

27. Tighten inner nut while rotating wheel hub in both

directions until there is a slight binding (Fig. 182).