1. Install seals.

2. Install boots.

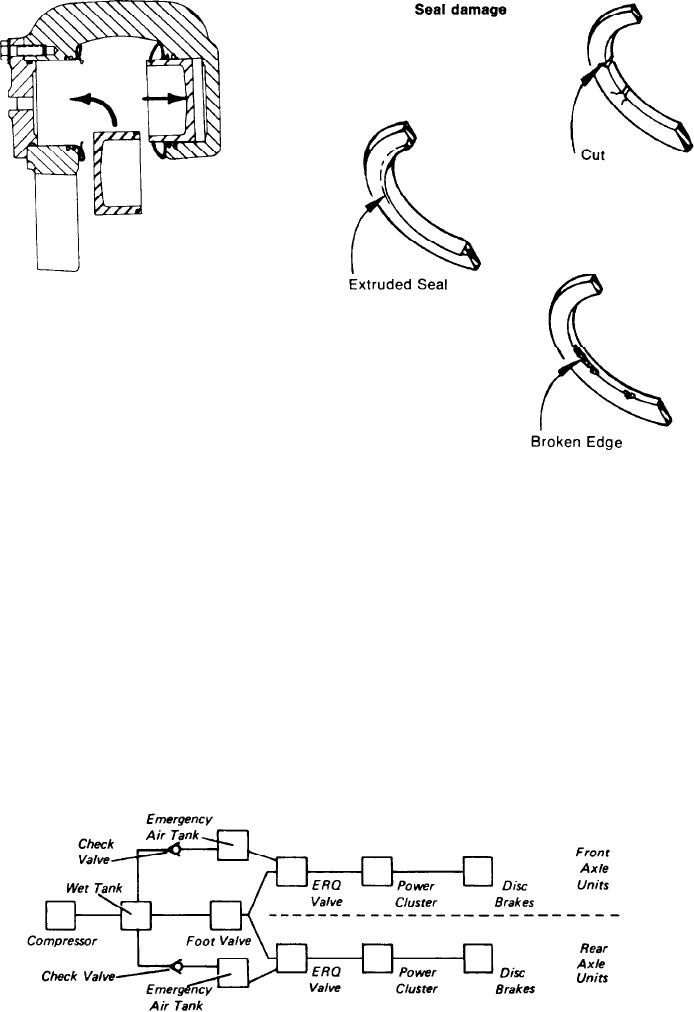

Replace seals if any

3. Replace pistons with pits or grooves.

of the described

conditions exist.

4. Push pistons through boot and seal. Lubricate

with caster oil, or system fluid-turn piston by

hand until located through seal.

NOTE: improperly located pistons and excessive

Persistant leaks after above repairs.

force (mechanical aids) will result in cut seals.

Check the brake head for cracks (caps-piston bores)

by using "spot check."

For more detailed instructions, see service manual.

plate.

175B EMERGENCY BRAKING SYSTEM,

AIR OVER HYDRAULIC

relay, quick release valve and an air tank. Any one

An air over hydraulic, emergency braking system

of these three units or their connecting lines on one

is used on the 1758 tractor shovel. The system pro-

axle can fail and the units on the other axle will still

vides both manual and automatic emergency stop-

apply the brakes.

ping in the event of an air or brake fluid loss.

Schematically the system looks like this:

Each axle has a power cluster (air over hydraulic

brake master cylinder), a combination emergency,

[4]