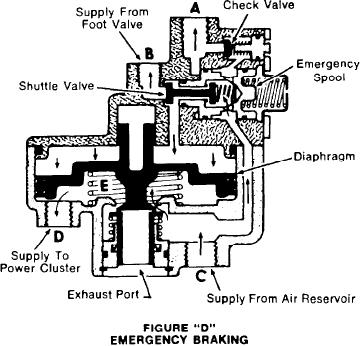

emergency tank to enter the top side of the dia-

APPLYING THE BRAKES

phragm. The diaphragm is pushed down allowing

(Figure "C") When the foot valve is pushed, air

e m e r g e n c y tank pressure to flow past the dia-

enters at port "B" and forces the diaphragm down,

phragm seat at "E" and out port "D" to the power

aiganst spring tension. As the diaphragm moves

cluster. The valve will remain in this position until

down, the diapraghm seat at "E" is opened and air

air pressure builds high enough to force the check

pressure from the air tanks flows thru port "D" to

valve from its seat, charge the emergency tank, and

the power cluster applying the brakes. When the

force the emergency spool back to the right against

foot pedal is released, air is exhausted thru port

spring tension.

"B" to the foot valve and through the exhaust port

of the valve body.

TROUBLESHOOTING THE ERQ VALVE

Examine the system frequently for air leaks and

make certain the air pressure is a minimum of 80

PSI. The maximum braking force available at the

w h e e l s is proportional to the air pressure in the

system. A system pressure of 80 PSI will not give as

effective braking as a system pressure of 100 PSI.

CHECKING THE "AUTOMATIC APPLY

OPERATION"

1. Run the engine until maximum air reservoir pres-

sure is reached, then stop the engine.

2. Open the drain cock in the main air tank until all

the air is drained from tank.

3 . The brakes should automatically apply-check

to see that they have.

AUTOMATIC APPLICATION OF BRAKES

4. Open the drain cocks in the emergency tanks

(Figure "D") In an emergency situation if either

and see that both tanks have pressure in them.

port "B" or port "A" is exhausted because of a rup-

tured line, there is a pressure drop on the left side

If the brakes do not

apply and the emergency

of the emergency spool. (Compare the position of

t a n k s have pressure in

them, examine the ERQ

the emergency spool in figure "C" and figure "D".)

valves for dirt, water and

air leaks. The ERQ valves

Immediately the emergency spool moves to the left

can be disassembled and

cleaned. A kit is available

u n d e r spring tension. The check valve seats, pre-

to overhaul them.

v e n t i n g emergency tank pressure from escaping

thru port "A". The shuttle valve seats the emergency

If the brakes do not apply and the emergency

s p o o l preventing air pressure from escaping thru

tanks have no pressure in them, examine the system

port "B"' and the foot valve. As the shuttle valve

for air leaks, especially the check valves.

shifts to the left, it allows air pressure from the

[7]