Probable causes:

port "D" and charge the emergency tanks thru port

"C", until the pressure in the system becomes great

1. Dirt blocking by-pass port

enough to move the emergency spool to the right

2. Swollen cup seal blocking the port (Swollen

against spring tension.

cup seals are caused by using the wrong brake

fluid.)

Problem 5: Air in the hydraulic lines.

P r o b a b l e causes:

1. Low fluid level

2. Blocked filler cap vent

3. Worn cup seals

4. Residual check not seating

Problem 6: Poor braking.

P r o b a b l e causes:

1. Low air pressure

2. Low fluid level

3. Air in the hydraulic system

4. Oil leaks in the system

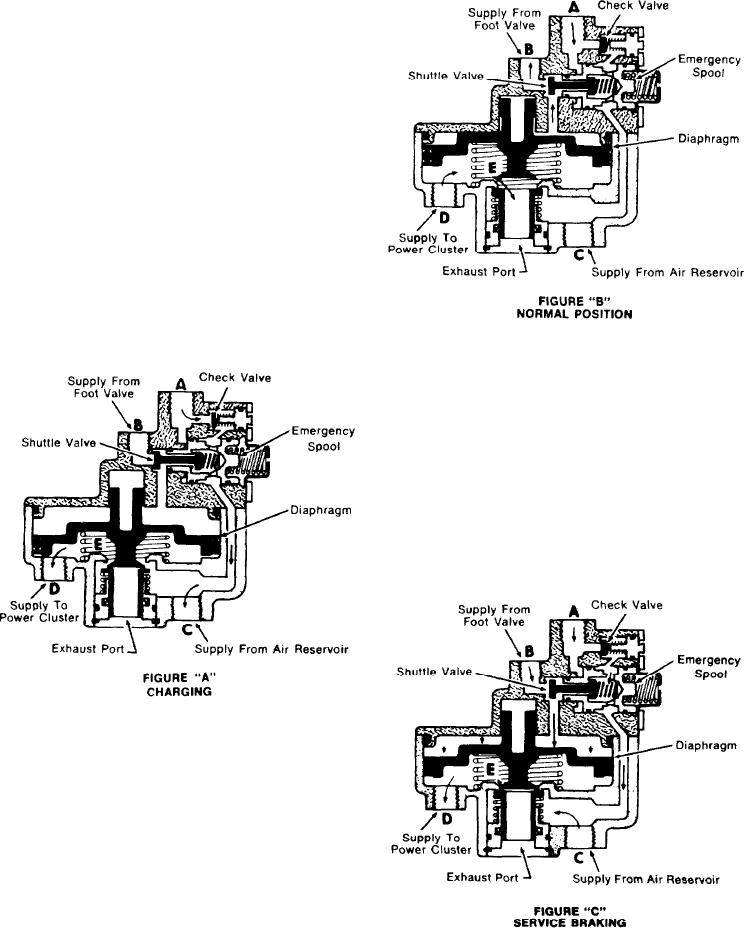

OPERATION OF THE EMERGENCY,

AIR TANKS FULL-BRAKES RELEASED

RELAY, QUICK RELEASE VALVE

(Figure "B") When the air pressure in the system

becomes great enough, the emergency spool moves

to the right against spring tension. The shuttle valve,

within the emergency spool, moves left. The air that

was on top of the diaphragm is exhausted thru port

"B" which leads to the foot valve. The diaphragm is

pushed up by the large spring. The air that was in

the power cluster exhausts thru port "D", past the

diaphragm seat at "E", and out the exhaust port.

A i r trapped in the emergency tank because the

shuttle within the emergency spool is closed and

the check valve is closed.

CHARGING THE SYSTEM

(Figure "A") When the engine is started with the

system empty, air from the compressor enters the

valve at port "A". Air lifts the check valve from its

s e a t : flows thru the emergency spool which is

moved to the left by spring tension, and thru the

passage in the right side of the valve to port "C"

Port "C" leads to the emergency tank. Air also

flows past the seat on the diaphragm at "E", and

thru port "D" which leads to the power cluster. Air

p r e s s u r e will hold the power cluster applied thru

[6]