HUSCO GENERAL TROUBLESHOOTING GUIDE

If the hydraulic system does not function proper-

Relief pressures

ly, check the following in the order listed. The hy-

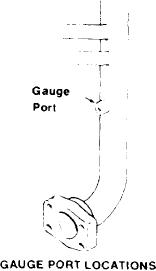

Install a 3000 psi (210,92 kg./cm. 2 ) hydraulic

d r a u l i c oil must be at operating temperature, a

gauge in the verticle pipe on the left side of the

minimum of 150F% (66C), before any of the follow-

front frame. (See diagram). Measure all pressures

ing checks are made. After you have performed the

at this point. This pipe connects the pumps to the

n e c e s s a r y checks and adjustments in one step,

main control valve.

operate the machine to see if the problem has been

corrected.

1. Hydraulic Fluid level (CAUTION: Hydraulic Res-

ervoir must not be overfull.)

2. Free Movement of Spools and Positive Detent

Feel in the Pilot Valve

3. Stall Speed

4. Relief Pressures

5. O p e r a t i n g Times (Boom &. Bucket Reaction

Times)

6. Main Spool Actuating Pressure

Relief pressure adjustments for the Husco valve.

7. Condition of Parts in Inlet Control Section

1. Warm the engine and transmission to operating

temperature. Warm the hydraulic fluid to 150F

8. Condition of Parts in Boom and Bucket Sections

10 (66C4C).

Free movement of spools and positive detent feel

2. Install a 3000 psi (210,92 kg./cm.2) gauge in the

vertical pipe on the left hand side of the front

With the engine shut off, move the control levers

frame.

in the cockpit back and forth to see that the linkage

is not binding and that the spools in the pilot valve

3. Accelerate engine to high free idle, roll bucket

are not sticking. While checking free movement of

b a c k and hold over relief. Read and record

spools, check to see that the detent positions are

positive and operating properly. If the pilot valve

pressure.

spools do not move freely or the detents do not posi-

tion properly, loosen the detent covers until the

4. Accelerate engine to high free idle, raise boom

to maximum height, hold over relief, read and

spools move freely. Then tighten the detent covers

slowly, making sure the spools continue to move free-

record pressure.

ly. If the air tanks have not been drained daily, it's

5. Compare boom up with bucket roll back pres-

possible that the detent mechanism contains water

and is rusted.

s u r e readings. Each should read the same. If

both pressures are low but equal the main re-

l i e f must be adjusted as outlined in the next

Stall RPM

step. If one reading, either boom up or bucket

Measure the stall RPM as outlined in the trans-

roll back is low, adjust the relief cartridge that

mission and converter troubleshooting section of

is low. Boom up and bucket roll back relief car-

this manual. If stall is low the machine will not have

tridges are set higher than main relief. In each

t h e necessary hydraulic power. Remember that

case the gauge should read main relief pressure.

stall must be measured with the engine and trans-

mission at operating temperature and with the main

6. To adjust the main relief, remove the inlet sec-

relief at the correct pressure setting.

tion cover of the main valve. Remove the main

[ 22]