When a relief cartridge is adjusted using the test

relief and flow control assembly. Loosen the

casting, only its cracking pressure (initial opening

lock nut on the assembly and turn the adjusting

pressure) is adjusted because a very low volume of

screw clockwise to increase pressure, counter-

oil is forced through the relief poppet. When the

c l o c k w i s e to reduce the pressure. One turn of

same cartridge is installed in the pilot valve it is

t h e adjusting screw will change the pressure

subjected to much higher flow from the pump. If

approximately 600 psi (42,184 kg./cm. 2) on the

t h e relief pressure setting of this cartridge was

475.

checked in the machine the pressure reading on

7. Dump the bucket fully, hold over relief and read

the gauge could vary as much as 800 psi (56,25

t h e gauge. If the pressure is incorrect adjust

k g . / c m . 2 ) . Because of this, a cartridge must be

the bucket dump relief cartridge.

checked and adjusted in a test casting.

8. Power down on the boom, hold it over relief and

read the gauge. If the relief pressure is incor-

PRESSURE SETTINGS

rect, adjust the boom down relief cartridge.

175

CIRCUIT

NOTE: The bucket dump and boom down relief

2200 psi 50 psi

Main relief

cartridges should be checked only after the main

(157 3.5)

(in machine)

relief has been checked and adjusted.

2600 psi 50 psi

Boom up

CAUTION: Do not work under the bucket or

(182 3.5)

(in test block)

boom mechanism while the boom is in the raised

2600 psi 50 psi

Bucket up

position.

(162 3.5)

(in test block)

IMPORTANT: Do not adjust overload reliefs in

1750 psi 50 psi

Boom down

the machine. Use a test casting and follow the in-

(122 3.5)

(in test block)

structions given below.

1750 psi 50 psi

Bucket down

(122 3.5)

(in test block)

PROCEDURE FOR SETTING

O V E R L O A D RELIEF CARTRIDGES:

OPERATING TIMES

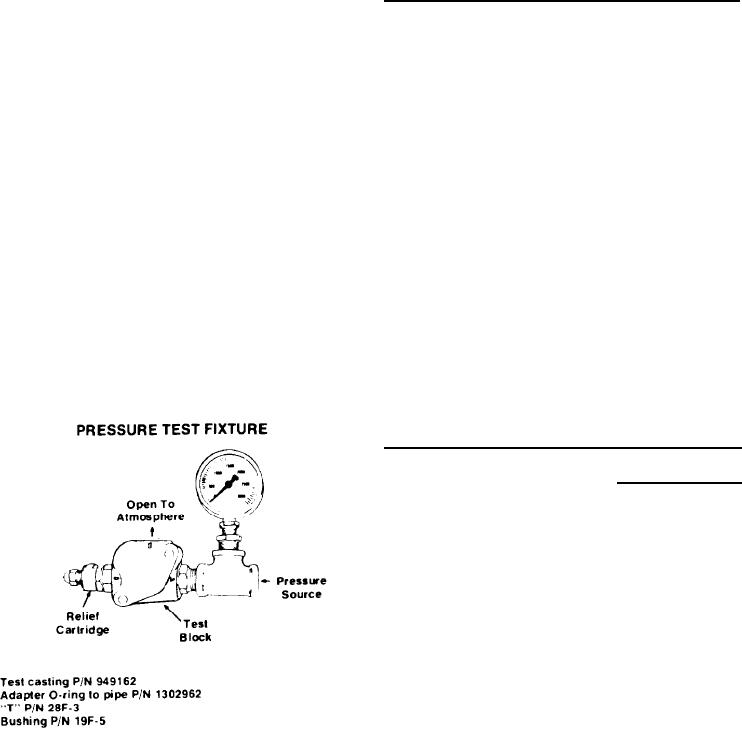

Install the overload relief in the test casting as

Check the time necessary to perform each hy-

shown in the diagram. Use a port-o-power or simi-

draulic operation of the machine. If the operation

lar device that will develop the necessary hydraulic

times do not agree with the following list, see the

pressure.

pages listing problems, causes, and remedies. The

checks are to be made with an empty bucket, the

Adjust the relief cartridge until the gauge indi-

engine at high idle, and hydraulic fluid at operating

cates the correct cracking pressure.

temperature.

TIME (Seconds)

OPERATION

175

6.5

Boom Raise

(From ground level to max. height)

4.1

Float Down

(From max. height to ground)

2.5

Bucket Rollback

(Full dump to full back)

1.9

Bucket Dump

(Boom raised way -

full roll back to

full dump (against stops)

[ 23 ]