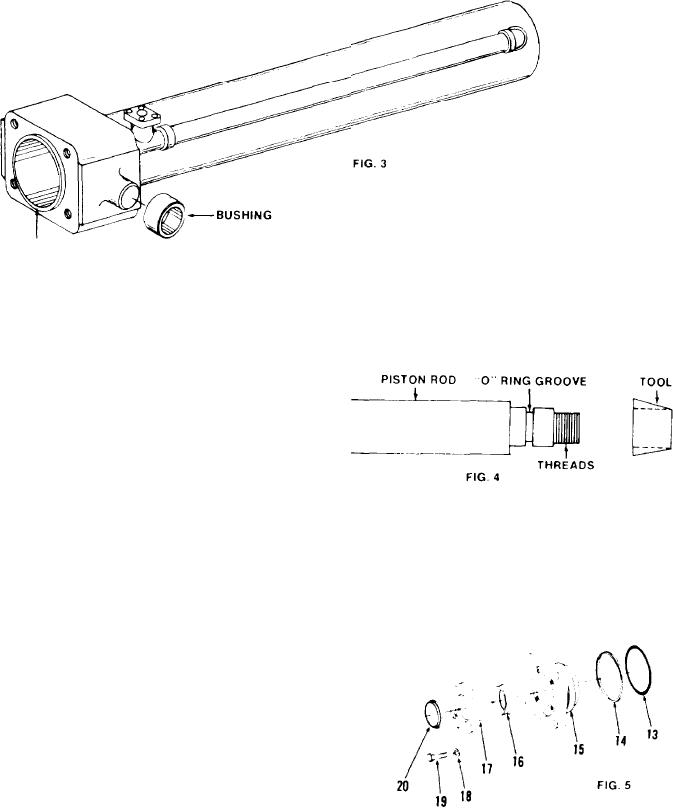

PISTON ROD PACKING

When assembling the piston rod packing, always

use new seals, "O" rings, back-up rings and dirt

wipers. It IS also recommended that a tool be fab-

CYLINDER INSPECTION

r i c a t e d which will aid in installing the packing

on the piston rod.

Examine the inside of the cylinder tube for ex-

cessive wear caused by dirt. foreign material or by

the piston contacting the cylinder wall. Usually the

majority of wear takes place in the center of the tube.

Cylinders can be bored as much as .010 inch(.254mm)

to clean up scratches and score marks. If more ma-

terial must be removed to clean away scratches, the

tube must be replaced because oversize pistons and

packings are not available.

The tool i S a cone which fits snugly on the rod

Examine the welds which hold the cylinder ends

where the piston would normally fit. The cone is

and pipe connecttons in place. Look for cracks and

tapered so that as the packing is slid over it. the

small holes. The best way to check them IS to pres-

lips on the seals are expanded and slide easily on-

surize the cylinder to 2500 psi (175 Kg/cm) and

to the main portion of the rod.

look for leaks.

If the piston rod packing is of the mono seal type,

Check the large opening in the end of the cylin-

follow these instructions:

der and the smaller holes which conduct oil into

and out of the cylinder to see that they are prop-

erly chamfered. Sharp edges in these areas will cut

piston seals.

If the cylinder mounting bushings are worn, re-

move them and press new bushing in place. Be sure

to align grease holes. Bushings on trunion mounted

cylinders (Fig 3) should be tack welded in 3 places

after being pressed into place.

1. Install back-up ring (14) and O-ring (13) on the

PISTON AND PISTON ROD

cylinder cap (15). The back-up ring sits next to

Examine the piston rod to see that it is not bent,

the O-ring opposite the side which receives the

scratched or pitted and the chrome plating IS in good

oil pressure.

shape. It may be necessary to press a new bushing

2. Place a thin coat of light grease on the mono

into the piston rod eye - if so make sure to align

the grease hole in the bushing with the one in the

s e a l (16) and slide the seal into the cylinder

cap (15). The lips of the seal must point toward

eye.

the oil pressure.

Examine the piston for scratches and wear marks.

Replace the piston if it shows signs of damage.

3. Press a new dirt wiper (20) into the mono seal

[54]