cap (17). Place the mono seal cap (17) into the

5. Press dirt wiper (23) in retainer (19) and fast-

cylinder cap (15) and secure with bolts and lock

en to cap with bolts (18). Do not tighten bolts

until the packing assembly has been installed or

washers (18 and 19).

the piston rod.

4. Place the special tool, described above, on the

piston rod and slide the packing assembly onto

6. Use a tool as shown in Figure 4 and install the

the rod.

packing assembly on piston rod. Tighten bolts

(18).

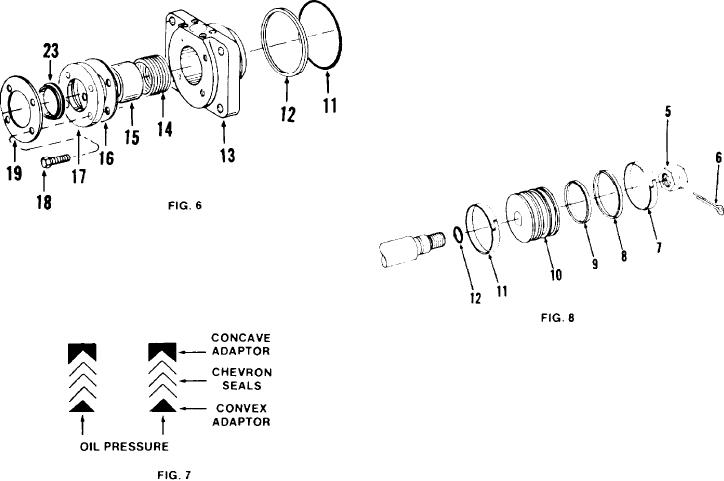

If the packing assembly is of the multiple Chev-

After the machine has been operating in the field

ron type, use the following assembly instruction:

for a time, it may be necessary to remove some of

the spacers (16) to tighten the packing and prevent

leaks.

P I S T O N AND PISTON SEALS

1. Place the back-up ring (12) and the O-ring (11)

on the cylinder cap (13). The back-up ring is

next to the O-ring opposite the side which re-

ceives oil pressure.

1. After the rod packing has been slid onto the rod,

place "O" ring (12) in the groove on the piston

rod. All pistons have this "O" ring and it must be

c h a n g e d each time the outer piston seals are

replaced.

2. Lightly coat the "O" ring (12) with grease and

carefully slide the piston (10) on the piston rod

and over "O" ring (12).

2. Place a thin coat of light grease on the Chev-

3. Install and torque nut (5). If the cylinder is re-

ron seals. Install the convex Chevron seal

built using the old piston rod it will have a cotter

adaptor first, then the Chevron seals, then the

pin or bolt hole already drilled in the end of the

c o n c a v e Chevron adapter in the cylinder cap

rod. Always torque the nut - if the hole in the

(13).

rod and in the nut are not aligned when properly

torqued, the nut may be tightened as much as 1/8

3. Install the bushing (15) on top of the Chevorn

of a turn to align the holes. Never loosen the nut

packing (14) and inside of the cylinder cap (13).

to align the holes. If necessary, drill a new hole

through both the nut and rod. Install the cotter

4 . Place spacers (16) four required, between cap

pin.

(13) and cap (17) and place cap (17) on cap (13).

[55]