An undercharged battery as evidenced by low

System output preferably should be checked at the

specific gravity readings and slow cranking.

"RATED VOLTAGE" given in the table.

An overcharged battery as evidenced by exces-

However, it IS permissible to check the output in

sive battery water usage.

amperes at any voltage within the "OPERATING

RANGE" listed in the table, since the current out-

These conditions can be caused by:

put will be quite close to the value that would be

o b t a i n e d a t " R A T E D VOLTAGE". The voltage

should never be allowed to rise above the "OPER-

I. A defective battery

ATING RANGE" for any length of time.

II. Poor circuit connections

III. A defective Integral Charging System

OPERATING

RATED

SYSTEM

I. BATTERY

RANGE

VOLTAGE

VOLTAGE

Since the battery may have an internal defect, it

26.0-30.0

28.0

24

must be checked to determine its condition. Ser-

vice Bulletin 7D-100E cover testing of batteries and

It should be noted that the voltage may be below

Energizers, respectively.

the "OPERATING RANGE" if the battery is in a

low state of charge. However, as the battery re-

II. CIRCUIT CONNECTIONS

ceives a charge, the voltage will rise to some value

within the "OPERATING RANGE."

Poor circuit connections in the 25 SI Integral

Charging System can cause an undercharged con-

dition only. Carefully Inspect all connections in-

c l u d i n g grounds between the Integral Charging

MAGNETIZING THE ROTOR

System and battery for cleanliness and tightness.

Insure that the battery cable clamps are clean and

The rotor normally retains magnetism to provide

tight, and that the battery IS dry and clean.

voltage build-up when the engine IS started. After

disassembly or servicing. however, it may be neces-

sary to re-establish the magnetism. To magnetize

III. INTEGRAL CHARGING SYSTEM

the rotor connect the Integral Charging System to

If the battery and circuit connection checks are

the battery in a normal manner, then momentarily

satisfactory, the Integral Charging System may be

connect a jumper lead from the battery positive

c h e c k e d either on or off the vehicle by making

post to the Integral Charging System relay terminal,

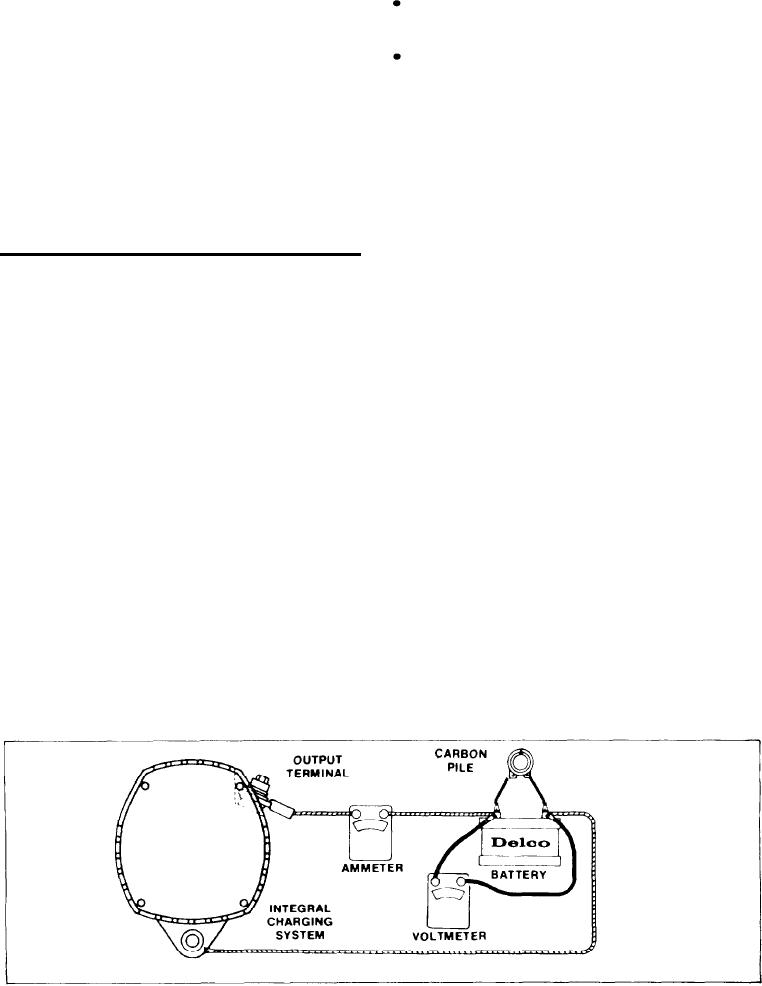

c o n n e c t i o n s as shown in Figure 4. Assemble a

identified in Figure 2. This procedure applies to

closed end terminal clip with 1/2 inch (12.7 mm)

b o t h negative and positive ground systems, and

hole to output terminal, then connect ammeter lead

will restore the normal residual magnetism in the

clip to this terminal clip.

rotor.

A

With the carbon pile turned off (open-

Trouble in the vehicle charging system will be

circuited), i n c r e a s e t h e I n t e g r a l C h a r g i n g

indicated by one of two conditions:

Figure 4--Output check (Remember-the hex bolt on the output terminal is electrically insulated)

[60]