To replace the drove end bearing:

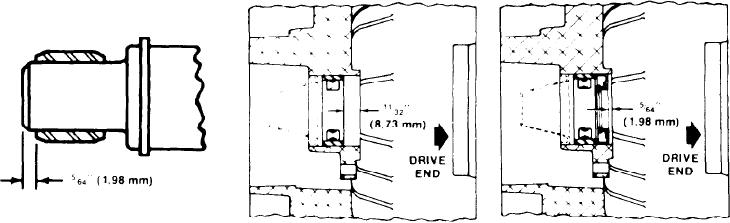

3. Push against the race only to install the new

b e a r i n g to the dimension shown in Figure 9.

1. Remove shaft nut, washer. pulley, fan, slinger

To facilitate the installation. heat the end frame

and the four retainer plate bolts. then remove

in an oven to 200 to 300F (90-150C). This will

t h e rotor and bearing assembly from the end

not damage the regulator.

frame.

4. Add Delco-Remy lubricant No. 1948791 to the

2. Pull the bearing from the rotor shaft, separate

filled. Arrange the lubricant so at least a portion

retainer plate and collar from shaft, and discard

seals in retainer plate and end frame.

will contact the bearing after assembly. Other-

wise the oil in the lubricant will not bleed to the

bearing. Press the cover into the housing.

3. Add Delco-Remy lubricant No. 1948791 so each

r e s e r v o i r between the bearing and seal after

assembly will be only three-quarters full Ar-

5. Add lubricant to the seal lip and fill the cavity

range the lubricant so at least a portion will con-

with lubricant between the rubber lip and steel

case of the seal. Install the seal with the lip

tact the bearing after reassembly. Otherwise the

towards the bearing to the dimension shown in

oil in the lubricant will not bleed to the bearing.

Figure 10.

Also add lubricant to each seal lip and fill the

cavity with lubricant between the rubber lip and

REASSEMBLY

steel case of each seal. The seals must be as-

Reassembly procedures are the reverse of dis-

sembled so the seal lip is toward or next to the

assembly. Torque the shaft nut to 70-80 lb. ft. (lo-

bearing.

11 kg./m.) Torque the output terminal bolt 100-

1 1 0 Inch-pounds (1.7-2 kg/cm.) when attaching

4 Lubricate collar. then install collar and retainer

cabel

plate, then press against the inner race only to

install the new bearing onto the shaft against

O U T P U T CHECK

the collar.

After disassembly and repair magnetize the rotor

5. The remaining assembly procedure is the re-

as covered on page 162, then recheck the integral

verse of disassembly.

Charging System by making connections as shown

in Figure 4. REMEMBER-If output terminal is red,

connect this terminal and ammeter to battery posi-

To replace the rectifier end frame bearing:

tive post, and battery negative post to generator

frame. If output terminal IS black. connect this ter-

1 Pull the old inner race from the shaft, and press

minal and ammeter to battery negative post, and

the new inner race on to the dimension shown

battery positive post to generator frame.

in Figure 8.

2. Discard the old seal, and push the old bearing

IMPORTANT--Battery or batteries must be fully

out of the housing from the inside toward the

charged when making OUTPUT CHECK after

outside.

repair.

-

-

Figure 8-Inner race location

Figure 9--Bearing location

Figure 10--Seal location

[64]