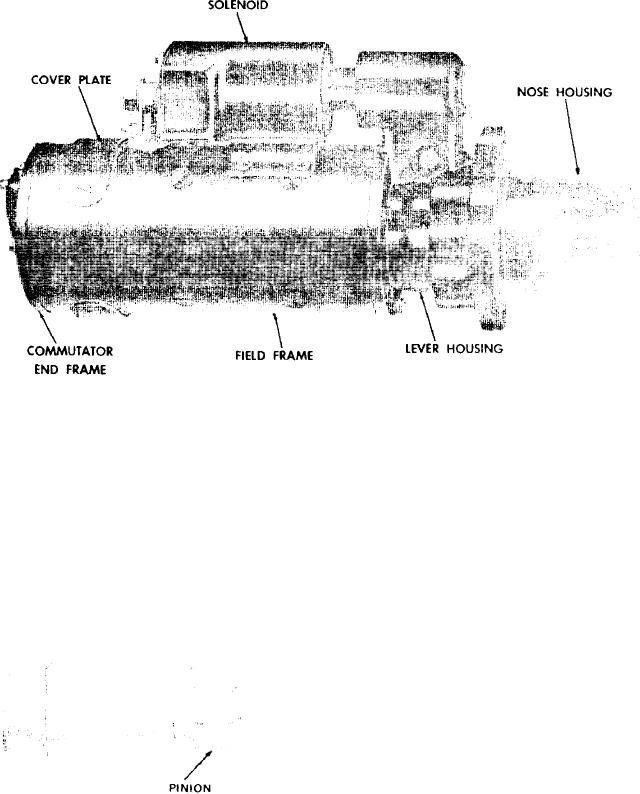

Enclosed Shift Lever Type

( H e a v y Duty) CRANKING MOTORS

Figure l-Typical enclosed shift lever type heavy duty cranking motor.

The heavy-duty cranking motor has a shift lever

Positive lubrication is provided to the bronze

and solenoid plunger that is totally enclosed to pro-

b u s h i n g s by an oil saturated wick that projects

tect them from exposure to dirt, icing conditions

t h r o u g h the bushings and contacts the armature

and splash.

shaft. Oil can be added in each wick by removing a

pipe plug which is accessible on the outside of the

motor.

A positork drive (fig. 2) is moved into mesh

with

the ring gear by the action of the solenoid. The

pin-

ion remains engaged until starting is assured

and

the solenoid circuit is interrupted. In case of a

butt

engagement, the motor will not be energized to

pre-

vent damage to the pinion and gear teeth.

MAINTENANCE

Under normal operating conditions, no mainten-

a n c e will be required between engine overhaul

periods. At time of engine overhaul motor should

be disassembled, inspected, cleaned and tested as

Figure 2-Positork drive.

described in succeeding paragraph.

[ 67 ]