Motor: If the battery, wiring and switches are in

OPERATION

satisfactory condition. and the engine is known to

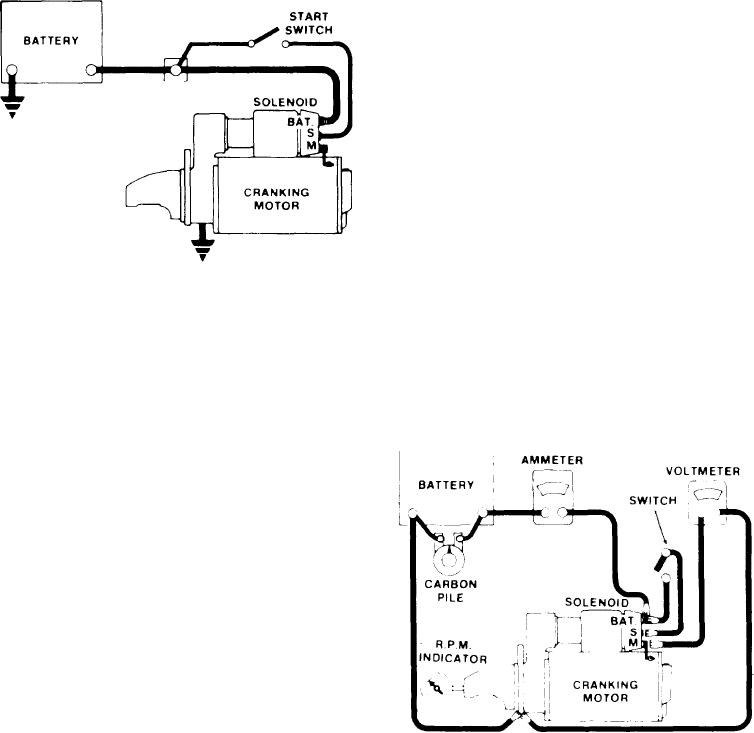

In the basic circuit shown in Figure 3. the sole-

be functioning properly, remove the motor and fol-

n o i d windings are energized when the swith is

low the test procedures outlined below.

closed The resulting plunger and shift lever move-

ment causes the pinion to engage the engine fly-

wheel ring gear and the solenoid main contacts to

CRANKING MOTOR TESTS

close, pinion overrun protects the armature from

excessive speed until the switch is opened. at which

R e g a r d l e s s of the construction. never operate

time the return spring causes the pinion to disen-

the cranking motor more than 30 seconds at a time

gage To prevent excessive overrun and damage to

without pausing to allow it to cool at least two min-

the drive and armature windings. the switch must

u t e s . On some appications. 30 seconds may be

be opened immediately when the engine starts.

excessive. Overheating. caused by excessive crank-

ing will seriously damage the cranking motor.

With the cranking motor removed from the en-

gine. the armature should be checked for freedom

of rotation by prying the pinion with a screwdriver

Tight bearings. a bent armature shaft. or a loose

pole shoe screw will cause the armature to not turn

freely. If the armature does not turn freely the mo-

tor should be disassembled immediately. However.

if the armature does rotate freely. the motor should

be given a no-load test before disassembly

No-Load Test (Fig. 4)

Connect a voltmeter from the motor terminal to

the motor frame. and use an r.p.m. indicator to mea-

s u r e armature speed. Connect the motor and an

ammeter in series with a fully charged battery of

Figure 3-Basic wiring circuit.

the specified voltage. and a switch in the open po-

sition from the solenoide battery terminal to the

s o l e n o i d e switch terminal Close the switch and

TROUBLESHOOTING THE

compare the r p m c u r r e n t and voltage reading

CRANKING CIRCUIT

with the specifications in Service Bulletins 1M-86

or 1M-187. It IS not necessary to obtain the exact

voltage specified in these bulletins. as an accurate

Before removing any unit in a cranking circuit

interpretation can be made by recognizing that if

for repair. the following checks should be made:

Battery: To determine the condition of the bat-

tery. follow the testing procedure outlined in Ser-

vice Bulletin 7D-100E Insure that the battery IS

fully charged

Wiring: Inspect the wiring for damage. Inspect

all connections to the cranking motor. solenoide.

magnetic switch. ignition switch or any other con-

trol switch and battery). Including all ground con-

nections Clean and tighten all connections as

required

Magnetic Switch, Solenoide and Control Switches:

Inspect all switches to determine their condition

Connect a jumper lead around any switch suspected

of being defective If the system functions properly

using this method. repair or replace the bypassed

Figure 4-No-load test circuit

switch.

[68]