TM 5-3805-258-24-1

9 5 0 B O P E R A T O R ’ S S T A T I O N

E L E C T R I C A L T R O U B L E S H O O T I NG

PROBLEM C: An Indicator That Must Be OFF, Is ON.

Possible Causes: a. Bad switch (sensor).

b. Bad ground wire to switch (broken wire or bad connec-

tion).

c. Bad control wire to switch (broken wire or bad connec-

tion ).

d. Bad operator panel.

TROUBLESHOOTING

1. Remove the control wire from the switch (sensor) and put it to machine

ground (See TABLE 3). The indicator must turn OFF.

I

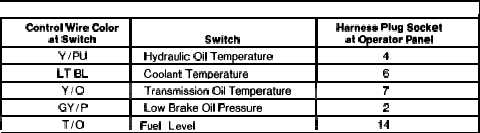

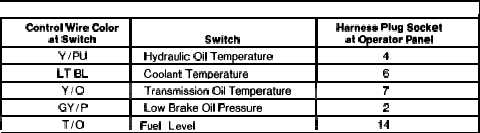

T A B L E 3

Control Wire Color

Harnesa Plug Socket

at Switch

Switch

at Operator Panel

YIPU

Hydraulic Oil Temperature

4

LT BL

Coolant Temperature

6

Y/o

I

Transmission Oil Temperature

I

7

GYIP

Low Brake Oil Pressure

2

I

T/O

] Fuel Level

I

14

Indicator Turns OFF

Indicator Stays ON

Either the switch or the ground is bad. Go to Step 2.

There is either an open wire in a harness, or the

operator panel is bad. Go to Step 3.

2. Check for continuity across the switch with an 8S4627 Circuit Tester.

Continuity

No Continuity

If there is continuity across the switch, then the

Replace the switch (sensor).

ground for the switch is bad. Replace the harness or

connect another ground wire to the switch.

3. Check for continuity through harnesses from the switch to the operator panel.

Fasten the control wire for the switch to machine ground. Disconnect the

harness plug from the operator panel and check for continuity at the plug socket

that is for the switch that is grounded (See TABLE 3). Use an 8S4627 Circuit

Tester.

Continuity

No Continuity

Replace the operator panel.

Use the electrical schematic or simplified schematic

to check through each harness between the switch

and the operator panel, until the one with the broken

wire is found. Repair or replace the harness.

4-113