TM 5-3805-256-24-2

ENGINE

DISASSEMBLY AND ASSEMBLY

FLYWHEEL

REMOVE FLYWHEEL

1156-11

Tools Needed

A

B

9S8500

Engine Stand

1

8S9908

Ratchet Puller

1

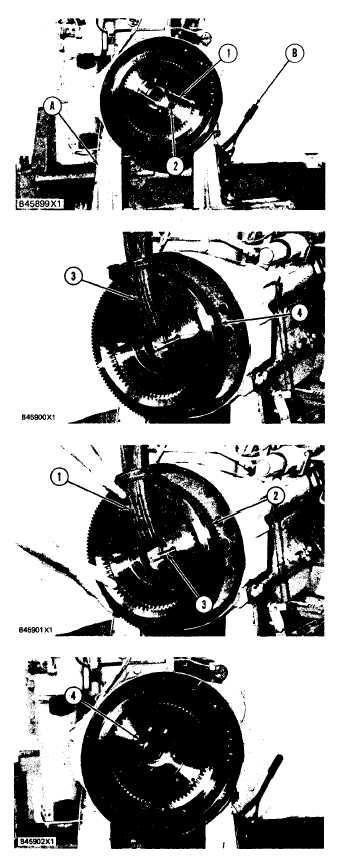

1.

2.

3.

4.

start by:

a) remove engine

Put the engine on tool (A) and use tool (B) to

hold the rear of the engine in place as shown.

Remove two bolts and install two 5/8”- 18 NF

twelve inches long guide bolts (1).

Remove the remainder of bolts (2) that hold the

flywheel to the crankshaft.

Move flywheel (4) on the guide bolts just far

enough to install strap (3) and a hoist. Remove

flywheel (4) from the engine. The weight of the

flywheel is 24 kg (53 lb.).

INSTALL FLYWHEEL

1156-12

Tools Needed

A

f

3

9S8500

Engine Stand

1

8S9908

Ratchet Puller

1

.

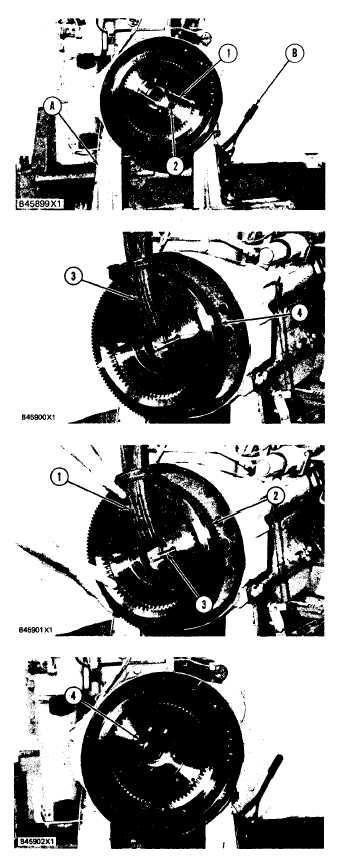

1.

2.

3.

4.

5.

If the flywheel ring gear has damage, a replace-

ment can be made as follows:

a) Heat the ring gear to a maximum (empera-

ture of 320°C (608°F) and install it on the

flywheel so the chamfer of the gear teeth

will be toward the starter pinion when the

flywheel is installed.

Install two 5/8”-18 NF twelve inches long

guide bolts (3) in the crankshaft.

Fasten strap (1) and a hoist to flywheel (2) and

install it on the guide bolts. Make sure the mark

on the flywheel is in alignment with the the mark

on the crankshaft.

Remove the strap and put the flywheel in posi-

tion on the end of the crankshaft.

Install bolts (4) that hold the flywheel to the

crankshaft. Tighten the bolts to a torque of 205

± 27 N·m (150 ± 20 lb.ft.).

end by:

a) install engine

5-156