TM 5-3805-262-20

3-18. SERVICE BRAKE SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

4. SERVICE BRAKES SQUEAK OR GROAN AT END OF STOP (Cont).

S t e p 1 . ( C o n t ).

Remove tire and wheel from axle end (page 8-4).

Check brake calipers for brake fluid leakage or sticking piston.

Repeat for other wheel and axle.

a. If brake caliper is leaking or piston sticking, replace brake

caliper (page 7-28).

b. If brake caliper is okay, go to step 2 below.

Step 2.

Check brake pads for wear (page 7-18),

or lubricant contamination.

a. Replace brake pads if worn, glazed,

uneven glaze, and brake fluid

or contaminated (page 7-19).

b. If brake pads are okay, check each disk for scored or grooved

condition (page 7-18). Notify next higher maintenance level to

replace disk if these conditions are seen.

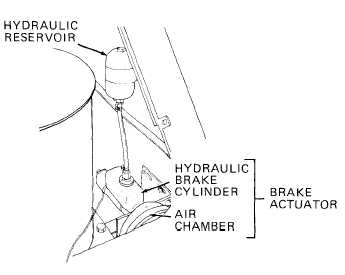

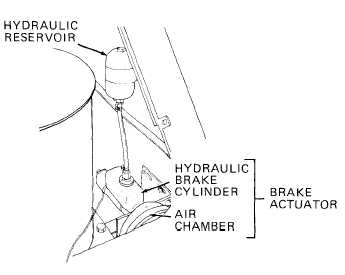

5. SERVICE BRAKES DO NOT STOP LOADER (AIR SYSTEM OPERATING OKAY).

Step 1.

Remove engine left side

panels (page 9-14) and

open front access door.

Bleed air from front and

rear brakes systems

(page 7-30).

Open air reservoir drain

valve and drain air.

At front brake actuator,

disconnect air hose con-

nected to elbow install-

ed in brake actuator air

chamber.

Connect a 9/16-18 street

tee to elbow.

Connect air hose discon-

nected from elbow above

t o s t r e e t t e e .

Connect zero to 150 psi pressure gage to street tee.

Close air reservoir drain valve .

Tell assistant to start and operate engine at 1000 rpm until AIR

PRESS gage needle indicates in green area.

3-116