TM 5-3805-262-20

3-18. SERVICE BRAKE SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

5. SERVICE BRAKES DO NOT STOP LOADER (AIR SYSTEM OPERATING OKAY) (Cont).

S t e p 1 . ( C o n t ) .

Tell assistant to press brake treadle and valve.

Pressure gage should indicate 90 psi minimum.

T e l l a s s i s t a n t t o s h u t o f f e n g i n e.

a .

b .

If pressure gage did not indicate 90 psi minimum, open air re-

servoir drain valve and drain air.

Disconnect pressure gage, air hose connected to street tee, and

s t r e e t t e e .

Connect air hose disconnected from street tee to elbow.

Go to step 3 below.

If pressure gage indicated 90 psi minimum, go to step 2 below.

Step 2.

Place blocks at each wheel

to prevent loader from

moving.

Engage transport/service

link (page 9-8).

Ensure that parking brake

i s a p p l i e d.

B e f o r e r a i s i n g l o a d e r f r o m

g r o u n d ,

b e s u r e t h a t

t r a n s p o r t / s e r v i c e l i n k i s

e n g a g e d.

Failure to do so may

c a u s e l o a d e r t o t u r n a n d s l ip

o f f j a c k s o r j a c k s t a n d s

c a u s i n g s e r i o u s i n j u r y o r

d e a t h.

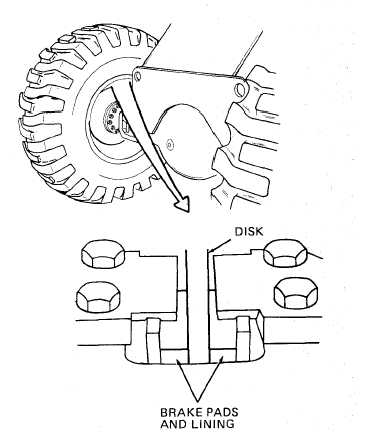

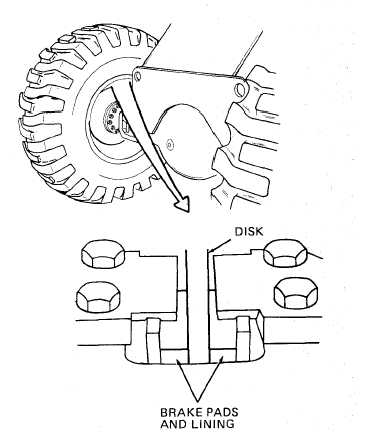

Raise front axle and wheel off

ground.

Remove tire and wheel from axle end.

T e l l a s s i s t a n t t o s t a r t a n d o p e r a te

engine at 1000 rpm until AIR PRESS

gage needle indicates in green area.

T e l l a s s i s t a n t t o p r e s s b r a k e t r e a d le

and valve while you check if brake

pads move inward.

T e l l a s s i s t a n t t o s h u t o f f e n g i n e.

3-117