TM 5-3805-262-20

3-18. SERVICE BRAKE SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

5. SERVICE BRAKES DO NOT STOP LOADER (AIR SYSTEM OPERATING OKAY) (Cont).

S t e p 2 . ( C o n t ).

a. If brake pads did not move, replace front brake actuator (page

7 - 5 1 ).

b. If brake pads did move, replace rear brake actuator (page 7-51).

Step 3.

Open air reservoir drain

valve and drain air.

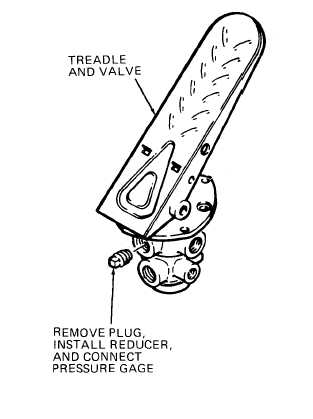

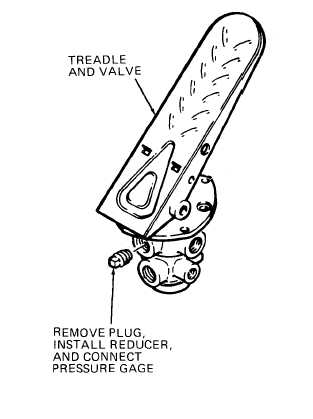

Remove one plug from

brake treadle and valve

upper chamber and in-

stall 1/2 to 1/8 NPT re-

ducer .

Connect zero to 150 psi

pressure gage to reduc-

er. Pressure gage hose

should be long enough so

that you can read

pressure gage in cab.

C l o s e a i r r e s e r v o ir

drain valve.

Start engine and operate

at 1000 rpm until low

air pressure buzzer

stops sounding.

Slowly press brake trea-

dle and valve while

watching pressure gage.

Pressure gage shall in-

d i c a t e i n c r e a s i n g a i r

pressure as brake trea-

dle and valve is

p r e s s e d .

a. If pressure gage does not indicate increasing air pressure, re-

place brake treadle and valve (page 7-53).

b. If pressure gage indicates increasing air pressure, go to step 4

below.

3-118