TM 5-3805-262-20

3-24. ACCESSORIES TROUBLESHOOTING)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. AIR HORN DOES NOT SOUND WHEN HORN VALVE DEPRESSED.

Step 1.

Install transport/service link to prevent loader from turning.

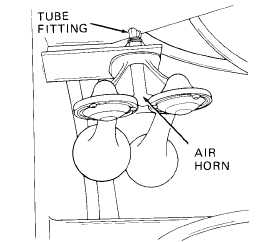

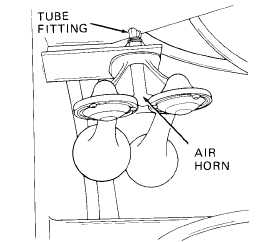

Crack (loosen) tube fitting at air horn.

B e f o r e p e r f o r m i n g t h e f o l l o w i n g s t e p s , b e s u r e t h a t t r a n s p o r t / s e r v i ce

l i n k i s e n g a g e d.

Failure to do so could cause serious injury or death

due to chassis pivoting and crushing you when you are working in area

between front and rear chassis.

Tell assistant to start engine and

allow air pressure to build up as

indicated by AIR PRESS gage indica-

t i o n .

Tell assistant to press horn valve.

Hissing should be heard from tube

fitting connection loosened above.

Step 2.

a .

b .

If hissing is heard, remove and

repair air horn (page 10-8).

Replace air horn diaphragm if

damaged (page 10-9).

I f h i s s i n g i s n o t h e a r d , t e ll

a s s i s t a n t t o s h u t o f f e n g i n e.

Tighten tube fitting connection loosened above, then go to step

2 below.

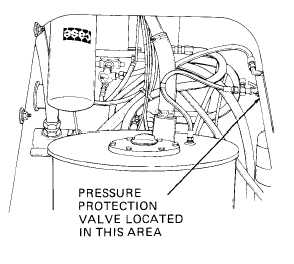

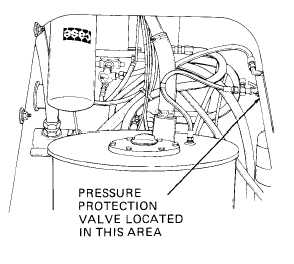

Drain air from air reservoir by

opening drain valve located at

bottom of air reservoir.

Unlock and open front access

door .

Disconnect air hose connected

between horn valve and tee

f i t t i n g i n s t a l l e d i n p r e s s u re

protection valve port at tee

f i t t i n g .

Connect a zero to 200 psi

pressure gage to adapter

i n s t a l l e d i n t e e f i t t i n g .

Close air reservoir drain valve.

3-158