TM 5-3805-262-20

3-31. FUEL SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. LOW FUEL PRESSURE (Cont) .

Step 5.

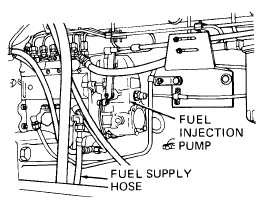

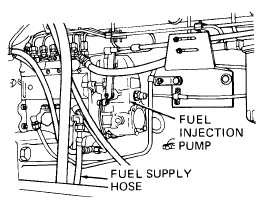

Disconnect fuel supply hose at

fuel injection pump feed pump.

Hold end of fuel supply hose

v e r t i c a l l y .

T e l l a s s i s t a n t t o t u r n i g n i t i o n

key switch to on position.

Check that fuel is pumped through

fuel supply hose.

T e l l a s s i s t a n t t o t u r n i g n i t i on

key switch to off position.

a .

b.

If fuel is pumped through fuel supply hose, hold fuel supply

hose vertically to keep it filled with fuel. Reconnect fuel

supply hose to fuel injection pump feed pump. Go to step 6

below.

If fuel is not pumped through fuel supply hose, go to step 8

below.

Step 6. At fuel injection pump feed pump, loosen bail lock nut.

Lower and remove fuel bowl with gasket, element, and spring.

Check fuel element for varnish coating or clogged condition.

Check fuel bowl for sediment.

a. If fuel element is coated with varnish or clogged, service it

(page 4-19); if sediment in fuel bowl, clean fuel bowl (page

4-19). Go to step 7 below.

b. If fuel element and fuel bowl are okay, install spring, fuel

element, and gasket in fuel bowl. Install fuel bowl with in-

stalled parts. Slide bail into position and tighten lock nut

finger tight. Go to step 7 below.

Step 7.

Bleed air from fuel system (page 4-40).

Tell assistant to crank engine for 30 seconds while you watch VTM

d i s p l a y .

VTM display should indicate 20 to 30 psi.

3-250