TM 5-3805-262-20

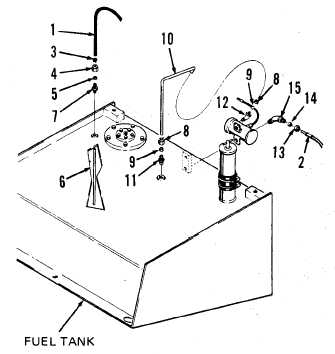

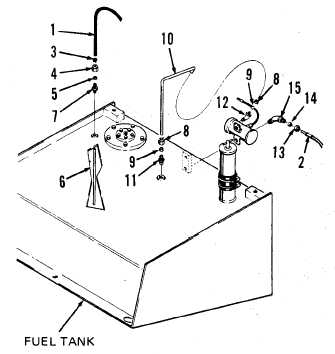

INSTALLATION (SHEET

(7)

( 8 )

( 9 )

(10)

(11)

(12)

(13)

(14)

(15)

P o s i t i on

2 OF 2)

two compression nuts

(8) and compression sleeves (9)

on fuel suction tube (10) .

I n s t a l l f u e l s u c t i o n t u b e ( 1 0 ),

with compression sleeves (9)

and compression nuts (8) in-

s t a l l e d , t h r o u g h f i t t i n g ( 1 1 )

until tube (10) touches bottom

of fuel tank. Position compres -

s i o n s l e e v e ( 9 ) i n f i t t i ng

(11), then tighten compression

nut (8) securely using open end

wrench.

Connect opposite end of fuel

suction tube (10) to elbow

(12). Position compression

sleeve (9) in elbow (12) then

tighten compression nut (8)

securely using open end wrench.

I n s t a l l f i t t i n g ( 7 ) i n f u e l

tank and tighten securely using

open end wrench.

Position compression sleeve (5) and compression nut (4) on tube (6);

install tube (6) through fitting (7) until tube touches bottom of fuel

tank. Position compression sleeve (5) in fitting (7) and tighten

compression nut (4) securely using open end wrench.

Place clamp (3) on tube (6).

Connect fuel return hose (1) to

t u b e ( 6 ) .

Using pliers, expand clamp (3)

and position clamp over fuel

return hose (1) to secure it to

tube (6). Release clamp (3).

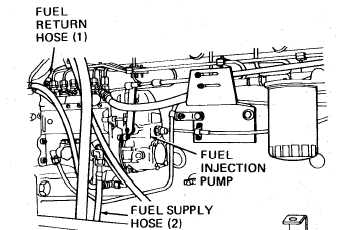

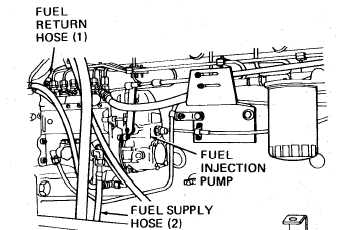

Reconnect fuel supply hose (2)

and fuel return hose (1) to

fuel injection pump. Tighten

fittings securely using open

end wrench.

Bleed air from fuel system (page 4-40).

Start engine and run at idle speed. Check hoses, lines, and fittings

installed above for fuel leakage. Tighten fittings if necessary. Shut

engine off.

Reinstall engine side panels (page 9-17).

4-13