2-8.

TM 5-3805-262-20

b. Raise loader bucket three feet above the ground as follows:

( 1 ) A t t a c h a c h a i n h o i s t t o l o a d e r b u c k e t.

(2) Pull LIFT ARM control lever back to RAISE position.

(3) Raise loader bucket and release LIFT ARM control lever. Bucket will

remain in raised position.

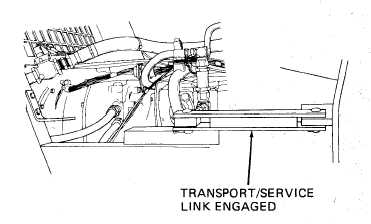

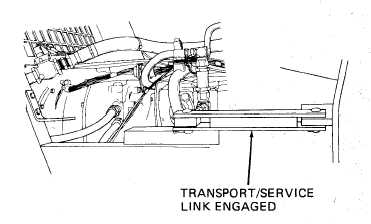

c. Place transport/service link in engaged position. If loader is turned to one

s i d e:

( 1 ) C l e a r p e r s o n n e l f r o m a r e a.

(2)

(3)

(4)

Pull fuel shut-off knob all the way out.

Turn ignition key switch

t o s t a r t p o s i t i o n a n d at

the same time turn steer-

ing wheel. When loader is

s t r a i g h t , i n s t a l l t r a n s-

p o r t / s e r v i c e l i n k . D o n ’t

operate starter motor more

than 30 seconds at a time

without allowing two

minutes for it to cool.

Place ignition key switch

i n o f f p o s i t i o n.

d. Attach rigid drawbar to loader rear draw bar pin.

e. Ensure that transmission control lever is in neutral (N) position.

f. Remove the front and rear drive shafts (pages 6-34 and 6-45, respectively) if

loader is to be towed more that 1/2 mile.

g . I f p o s s i b l e , g e t a n a u x i l i a ry

h. Attach a second unit, such as

I f f r o n t o r r e a r a x l e f a i l u r e

air supply for loader brake system .

a dozer, to rear of loader as close as possible.

i s

remove axle shafts before moving

i. Tow disabled loader at a maximum

NOTE

suspected, notify direct support to

l o a d e r.

speed of five miles per hour.

The loader can be air transported in C-130, C-141, and C5A aircraft with cab removed

to reduce loader height to 106.5 inches. All removed parts shall be palletized for

air transport with the loader.

2-13