TM 5-3805-262-20

INSTALLATION

(1)

(2)

(3)

(4)

( 5 )

(6)

(7)

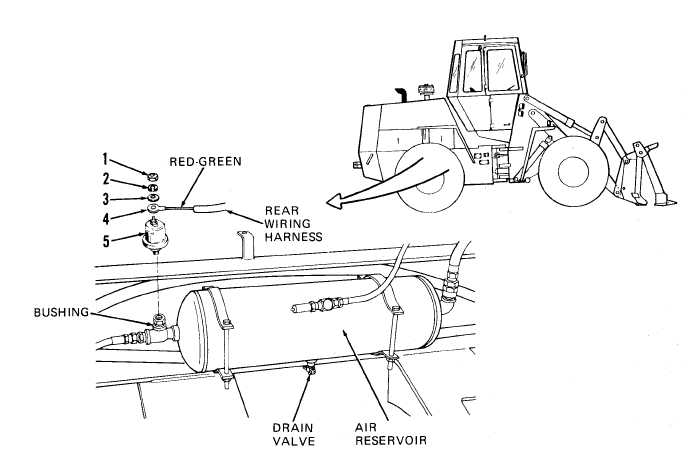

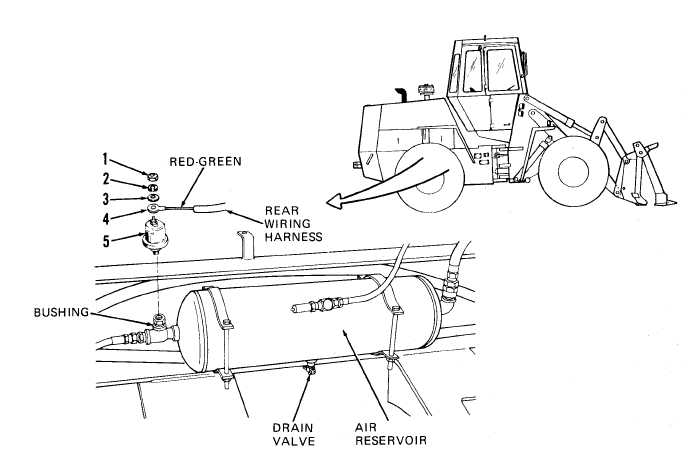

A t r i g h t s i d e o f a i r r e s e r v o i r,

i n s t a l l a i r p r e s s u r e s e n d e r ( 5 ) i n b u s h-

ing and tighten.

Connect terminal (4) to air pressure sender (5) and secure using washer

(3), lock washer (2), and nut (1).

Spray terminal (4) with electrical cleaner and allow to air dry. Then

s p r a y t e r m i n a l w i t h e l e c t r i c a l s e a l e r.

Close drain valve at bottom of air reservoir .

Start and operate engine at idle speed until air pressure gage located on

left instrument cluster indicates in green area of gage; then turn off

engine.

Apply detergent and water solution to air pressure sender and bushing and

check for air leakage. If leakage is seen as indicated by bubbles at

bushing, tighten air pressure sender.

If leakage continues, or if leakage

is from air pressure sender, replace air pressure sender.

I n s t a l l r i g h t f r o n t s i d e p a n e l ( p a g e 9 - 1 7 ).

5-139