TM 5-3805-262-20

OPERATING TEST

Open air reservoir drain valve to relieve all air system pressure before

d i s c o n n e c t i n g a i r s y s t e m c o m p o n e n t s o r l i n e s . F a i l u r e t o d o s o c o u l d

cause serious injury .

(1)

(2)

(3)

( 4 )

(5)

(6)

Open air reservoir drain valve to relieve air system pressure.

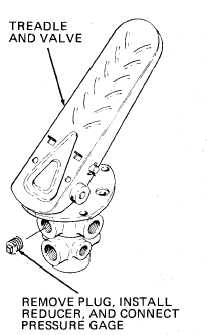

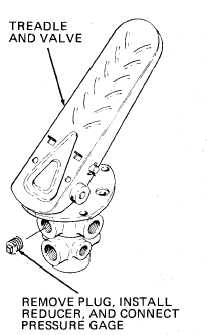

Remove one plug from valve upper chamber and install

1/2 to 1/8 NPT reducer.

Connect zero to 150 psi pressure gage to reducer.

Pressure gage hose must be long enough so that you

can read pressure gage in cab.

Close air reservoir drain valve.

Start engine and operate at idle speed. Continue to

operate engine until air pressure gage indication on

left instrument cluster no longer increases.

Slowly press treadle and valve while watching pres-

sure gage. Pressure gage shall indicate increasing

air pressure as treadle and valve is pressed.

(7) Operate engine at 1000 rpm until air pressure gage

indication on left instrument cluster no longer in-

creases. Press treadle and valve down completely.

Pressure gage connected to valve port shall indicate

approximate pressure in air reservoir. Correct pres-

sure is approximately 110 psi when treadle and valve

i s f u l l y p r e s s e d .

(8) Release treadle and valve. Pressure gage connected to

indicate zero psi. Turn off engine.

v a l v e p o r t s h a ll

Relieve all air system pressure before disconnecting air system compo-

nents or lines. Failure to do so could cause serious injury.

( 1 0 ) O p e n a i r r e s e r v o i r d r a i n v a l v e t o r e l i e v e a ir

(11) Disconnect air pressure gage from valve port.

plug in valve body.

(12) Close air reservoir drain valve and close and

system pressure.

Remove reducer and install

lock front access door.

7-55