TM 5-3805-262-20

INSPECTION

( d)

( e)

( f )

(g)

( h)

( i )

( j )

(k)

( l )

(m)

(n)

(o)

(SHEET 2 OF 3)

Inspect water hose (3) along its entire length for cracks, splits, worn

spots due to chafing, or other damage.

Check that clamp (4) securing water hose (3) to elbow (5) is tight and

that coolant leakage is not observed. Tighten clamp (4) if loose.

Check that clamp (6) securing water hose (8) to adapter (7) is tight and

that coolant leakage is not observed. Tighten clamp (6) if loose.

Inspect water hose (8) along its entire length for cracks, splits, worn

spots due to chafing, or other damage.

Check that clamp (9) securing water hose (8) to elbow (10) is tight and

that coolant leakage is not observed. Tighten clamp (10) if loose.

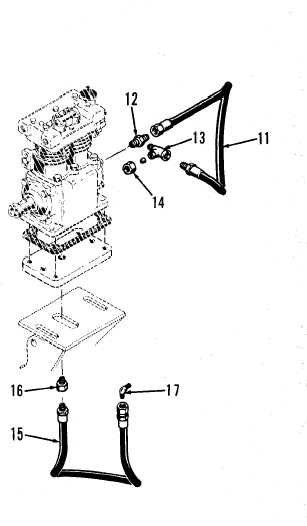

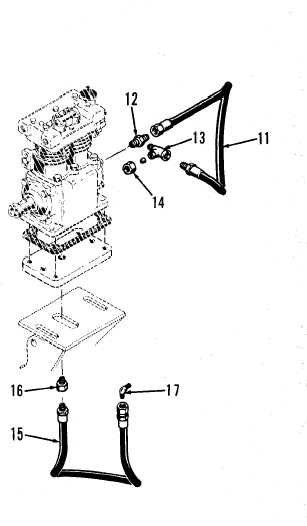

Check that oil inlet hose (11)

connection to adapter (12) is tight

and that oil is not leaking from

hose;

if necessary tighten hose

f i t t i n g .

Inspect oil inlet hose (11) along

i t s e n t i r e l e n g t h f o r c r a c k s,

splits, worn spots due to chafing,

or other damage.

Check that oil inlet hose (11)

connection to tee (13) is tight and

that oil is not leaking from hose;

i f n e c e s s a r y t i g h t e n h o s e f i t t i n g .

Check for oil leakage at nut (14);

if oil leakage is seen, tighten nut

(14) l

Check that oil return hose (15)

connection to reducer (16) is tight

and that oil is not leaking from

hose;

if necessary tighten hose

f i t t i n g .

Inspect oil return hose (15) along

i t s e n t i r e l e n g t h f o r c r a c k s,

splits, worn spots due to chafing,

or other damage.

Check that oil return hose (15)

connection to elbow (17) is tight

and that oil leakage is not

apparent; if necessary tighten hose

f i t t i n g .

7-103