TM 5-3805-262-20

7-3. AIR BRAKE SYSTEM MAINTENANCE (CONT)

g. Air Compressor Assembly

(cont).

(3) Air Compressor Governor (cont).

ADJUSTMENT (SHEET 1 OF 2)

Relieve all air pressure before working on air system. Failure to do so

c o u l d r e s u l t i n s e r i o u s i n j u r y . If you are injured obtain medical aid

immediately.

( a)

(b)

(c)

(d)

( e)

( f)

(g)

(h)

( i )

( j )

(k)

Open drain valve in bottom of air

r e s e r v o i r t o r e l i e v e a i r p r e s s u r e.

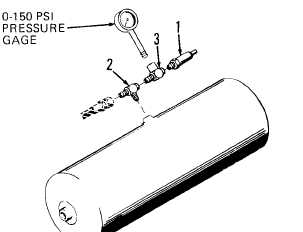

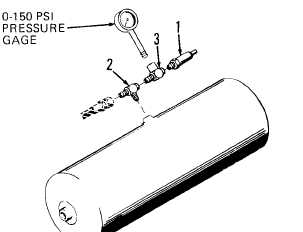

At top of air reservoir, remove

safety valve (1) from tee (2) and

install 1/4 NPTF street tee (3) in

t e e ( 2 ) . I n s t a l l s a f e t y v a l v e ( 1 ) in

s t r e e t t e e ( 3 ) .

Install zero to 150 psi air pressure

g a g e i n s t r e e t t e e ( 3 ).

Close drain valve in bottom of air

r e s e r v o i r .

Start engine and operate at idle speed.

Watch pressure gage. Pressure indication will increase until air com-

pression stops. When pressure indication stops increasing, record

p r e s s u r e i n d i c a t i o n . Pressure indication shall be 105 to 115 psi.

Continue to operate engine at idle speed. Apply brakes several times

while observing pressure gage indication. pressure indication will de-

crease until compression starts. When pressure indication just starts to

i n c r e a s e , r e c o r d p r e s s u r e i n d i c a t i o n. Pressure must be 90-95 psi.

If pressure indications recorded in

steps (f) and (g) above are not cor-

rect perform steps (i) through (1)

below otherwise go to step (m) below.

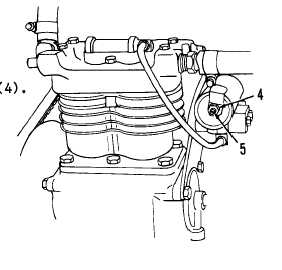

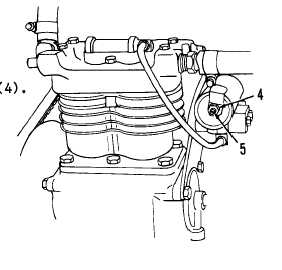

At governor assembly, loosen lock nut

Turn adjusting screw (5) clockwise to

decrease pressure setting, or counter-

clockwise to increase pressure

s e t t i n g.

Tighten lock nut (4) while holding ad-

justing screw (5) using screwdriver to

prevent adjusting screw from moving

and changing adjustment.

7-100