TM 5-3805-262-20

10-2. AIR HORN ASSEMBLY MAINTENANCE

This task covers removal, disassembly, cleaning, inspection, reassembly, and in -

stallation of air horn assembly.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Fixed open end wrench set

Socket wrench set, 3/8 inch drive

No. 1 Supplemental Organizational Maintenance Tool Kit

5/8-18NF die

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

Detergent (Appendix C, item 3)

Horn repair kit (FSCM 51511 PN 21320)

PERSONNEL REQUIRED: Two Construction Equipment Mechanics M0S 62B

NOTE

PRELIMINARY PROCEDURE: Front access door unlocked and open and air

reservoir drain valve opened.

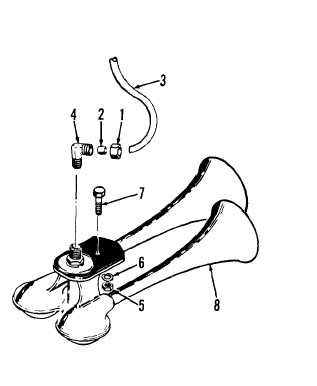

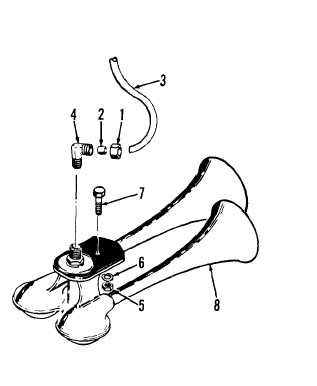

REMOVAL

a .

b .

c .

d.

Loosen nut (1) and disconnect tube (3)

from elbow (4). Don’t remove compression

sleeve (2) or nut (1) from tube (3).

If necessary, remove elbow (4) from air

horn assembly (8) port.

While assistant holds capscrews (7) using

socket wrench, loosen and remove two nuts

(5) and lock washers (6) while supporting

air horn assembly.

Remove air horn assembly (8) and two cap-

screws (7).

10-8