TM 5-3805-262-34

[ 3-10. PARKING BRAKE MAINTENANCE (CONT) ]

a.

Parking Brake Chamber (Cont).

DISASSEMBLY (SHEET 2 OF 2)

Spring (3) is under high tension.

Do not remove capscrews (7) unless

chamber tool is installed. Failure to do so could cause serious injury

due to flying parts caused by spring tension. If you or other personnel

are injured by flying parts, obtain medical aid immediately.

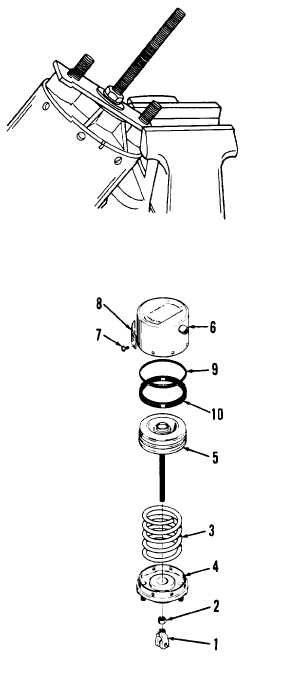

(7)

Remove eight capscrews (7) and

warning plate (8).

NOTE

It may be necessary to double nut shaft of

piston (5) to prevent shaft from moving

when performing following step.

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

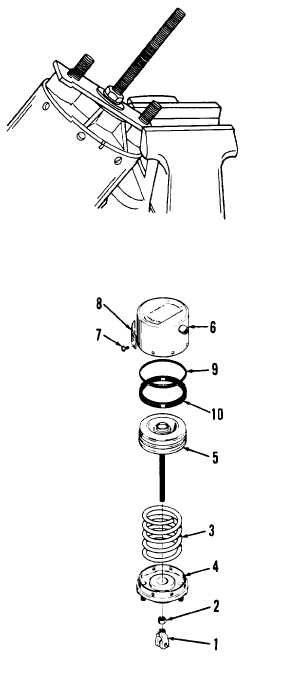

Install brake chamber in vise as

shown.

Loosen 3/4 NC nut on shaft of piston

(5) until spring (3) tension is re-

lieved. Do not remove nut.

Support cylinder (6) and remove 3/4

NC nut and 5/8 inch inside diameter

washer from shaft of piston (5).

Remove cylinder (6), piston (5), and spring

(3) from mounting plate (4).

Remove spring (3) from cylinder (6).

Remove piston (5) from cylinder (6).

Remove and discard O-ring (9) and wiper (10)

from piston (5).

Remove mounting plate (4) from vise.

Remove chamber tool from mounting plate (4).

LEGEND

1. Yoke

2. Nut

3. Spring

4. Mounting plate

5. Piston

6. Cylinder

7. Capscrews (8)

8. Warning plate

9. O-ring

10. Wiper

3-416