TM 5-3805-262-34

3-14. STEERING GEAR MAINTENANCE (CONT)

REASSEMBLY (SHEET 2 OF 3)

m.

n.

o.

p.

q.

r.

s.

t.

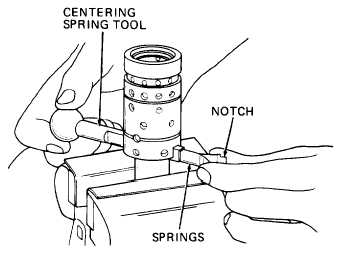

Put sleeve (30) and valve spool

(28) in soft jawed vise. Tighten

vise just enough to hold valve

spool and sleeve in position. Turn

sleeve and move it on valve spool

until spring slots in sleeve and

valve spool are alined. Put

centering spring tool through slot

for springs (29).

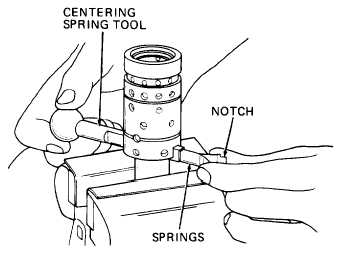

Put six springs (29) in sets of

three. Install two sets of springs

in slot at end of tool with

notched corners toward sleeve

(30).

into valve

Using thumb and finger to compress springs (29), push springs

spool (28) and sleeve (30) while withdrawing tool as necessary to put

springs in position.

Remove sleeve (30) and valve spool (28) with springs (29) installed from

vise. Install pin (27) through sleeve and valve spool, then install thrust

washer (26), bearing (25), and thrust washer (24) on valve spool (28).

Apply clean lubricating oil to outside of sleeve (30) and in bore of housing

(41).

Hold pin (27) in position and install sleeve (30) and valve spool (28) until

pin has started into bore of housing (41). Sleeve and valve spool must be

installed straight into housing. Turn sleeve and valve spool to make it

easier to install them in housing.

NOTE

If pin (27) moves out of sleeve (30) and valve spool (28), pin will stop

sleeve and valve spool from being installed in housing (41). To prevent

this, hold sleeve and valve spool in position in housing. Put end of

sleeve and valve spool on bench. Lower housing onto sleeve and valve

spool.

Apply oil-soluble grease to O-ring (20) and install O-ring in groove on

stator (22).

Apply clean lubricating oil to rotor (21). Aline rotor with stator (22) and

push rotor into stator.

3-520