TM 5-3805-262-34

4-1. ENGINE MAINTENANCE (CONT)

d. Crankshaft and Main Bearings (Cont).

INSTALLATION (SHEET 3 OF 5)

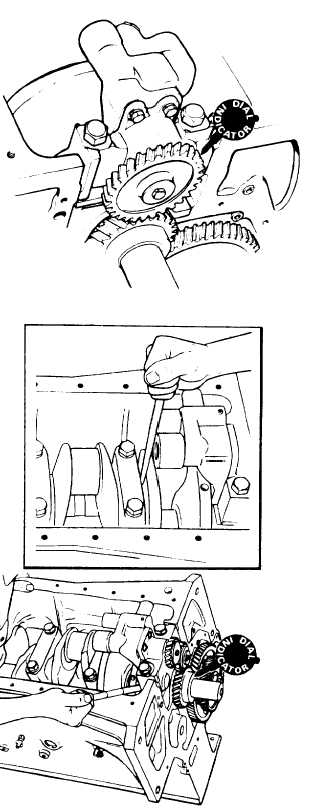

(19) Position dial indicator on oil pump

drive gear and check backlash be-

tween pump gear and crankshaft gear

(19). Backlash must be 0.006 to-

0.011 inch. If backlash is less than

0.006 inch or more than 0.011 inch,

add or subtract shims (8) between

oil pump and number 1 main bearing

cap (9) to obtain correct backlash.

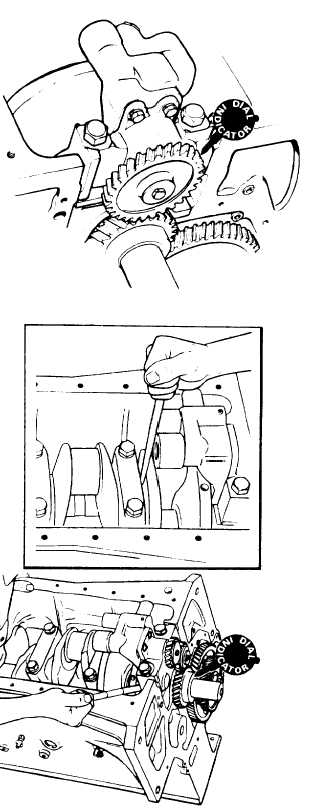

NOTE

To obtain an accurate reading in step

(20) below,

use a pry bar between

crank throw and number 2 or 4 main

bearing cap.

(20) Position dial indicator

against crankshaft gear

(19) and check crankshaft

end play. End play must

be 0.003 to 0.015 inch.

If end play exceeds 0.015

inch, install oversize

thrust washers (15) on

both sides of number 5

main bearing cap.

(21) Install pistons and

connecting rods (page

4-50).

(22) Install oil pump suction

tube (page 3-94).

4-30