TM 5-3805-262-34

INSPECTION/REPAIR (SHEET 3 OF 3)

(a)

(b)

(c)

(d)

(e)

Position main bearing caps (12

thru 14) in cylinder block.

Lubricate capscrew (10)

threads and under head using

OE/HDO 30 engine oil.

Install two washers (11) and

capscrews (10). Tighten to 195

to 215 lb-ft.

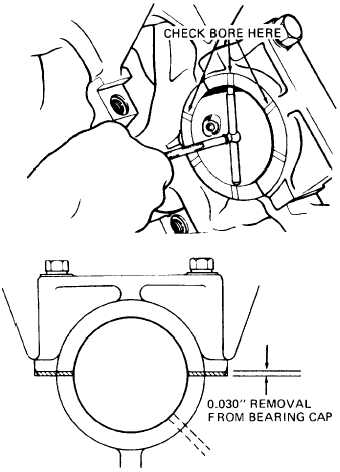

Check bore diameter using bore

gage at three angular loca-

tions as shown.

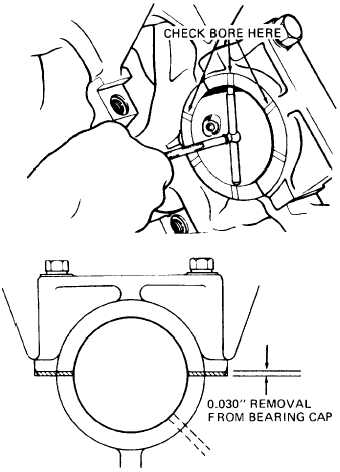

If bore diameter is not

3.191 to 3.192 inches (one

of three measurements may be

up to 0.0005 inch over spe-

cified dimensions and not

require reboring), bore out

to meet tolerance. If

vertical dimension is out of

tolerance or cap is shifted

sideways, rework cap by re-

moving 0.030 inch stock from

mating surface and then bore

out to meet above measure-

ment.

NOTE

To prevent bearing cap from wobbling, be sure to machine new mounting

surface flat.

(11) Inspect all other parts for cracks, excessive wear, or thread damage.

4-25