TM 5-3805-262-34

4-1. ENGINE MAINTENANCE (CONT)

d. Crankshaft and Main Bearings (Cont).

INSTALLATION (SHEET 1 OF 5)

When handling heated parts, always wear heat resistant gloves to prevent

burning your hands. If you burn your hands, get medical assistance imme-

diately.

(1)

Heat crankshaft gear (19) using gear and bearing heater.

(2)

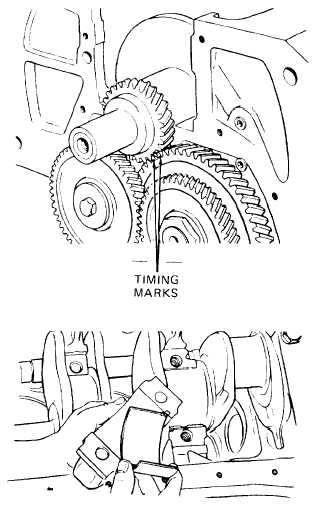

Install key (20) and crankshaft gear (19) on crankshaft (18). Be sure

that timing mark on gear is facing outward.

Don’t press on center of bearing liners when installing them. Always use

a sliding type movement. Failure to do so may cause damage to bearing

liners.

(3)

(4)

(5)

(6)

(7)

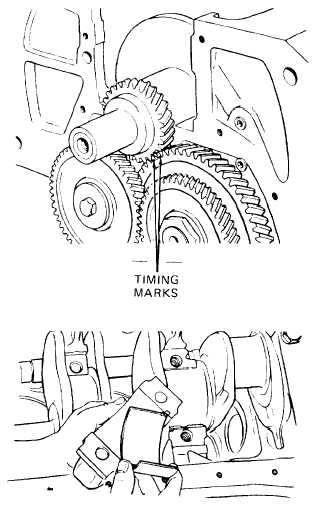

Install seven main bearing liners

(16 and 17) in cylinder block us-

ing a sliding type movement. Lu-

bricate liners using clean engine

oil.

Install crankshaft (18) in cylin-

der block, alining timing marks

on crankshaft gear (19) and

shaft gear.

Install seven main bearing l

(16 and 17) in bearing caps

12, 13, and 14) using a slid

cam-

iners

(9,

ing

type movement. Make sure bearing

liner lock lines up with bearing

cap lock groove.

Clean crankshaft (18) main

bearing journals and place a

piece of plastigage on each

journal..

Install six main bearing caps

(12 thru 14) in cylinder block.

4-26