TM 5-3805-290-10

RAIL TIEDOWN PROCEDURES ON A DODX RAIL CAR - CONTINUED

0024 00

924G WHEEL LOADER WITH FORKS AND 2-1/2-YARD BUCKET - CONTINUED

6.

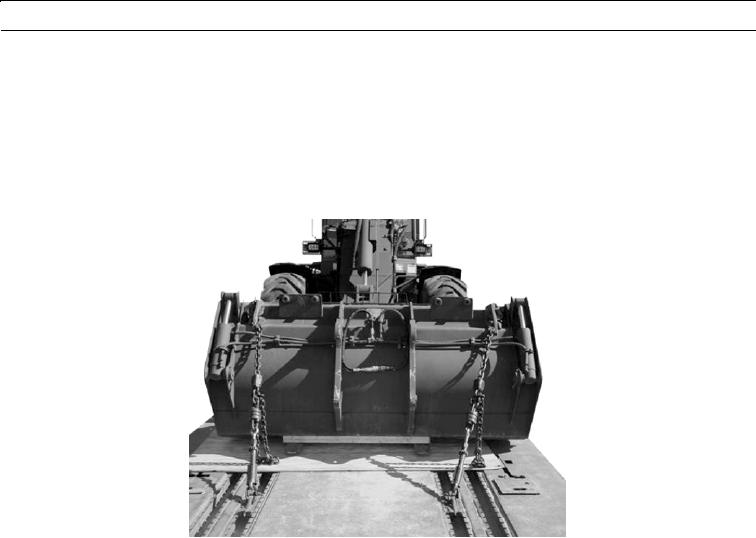

Attach tiedown chain which is closest to loader tire to tiedown provision on top of loader bucket and repeat for other

side of rail car. Tighten chains, which will rotate bucket towards loader slightly. Place a 2-in. x 3-in. x 4-ft timber under

back edge of bucket, between bucket and fork tines (as shown).

7.

Position tiedown chains in the inner rail in front of the bucket/fork carriage assemblage and secure the chains to the

bucket tiedown provisions. Shoe of tiedown provision should be positioned in rail to provide approximately a 45-degree

tiedown angle from horizontal.

427-B2140

FOL Bucket Front Tiedown. Note Wooden 2-in. x 3-in. x 4-ft Timber

Originally Placed Along Bucket Aperture.

0024 00-2