TM 5-3805-290-23-1

TROUBLESHOOTING WITHOUT A DIAGNOSTIC CODE - CONTINUED

0008 00

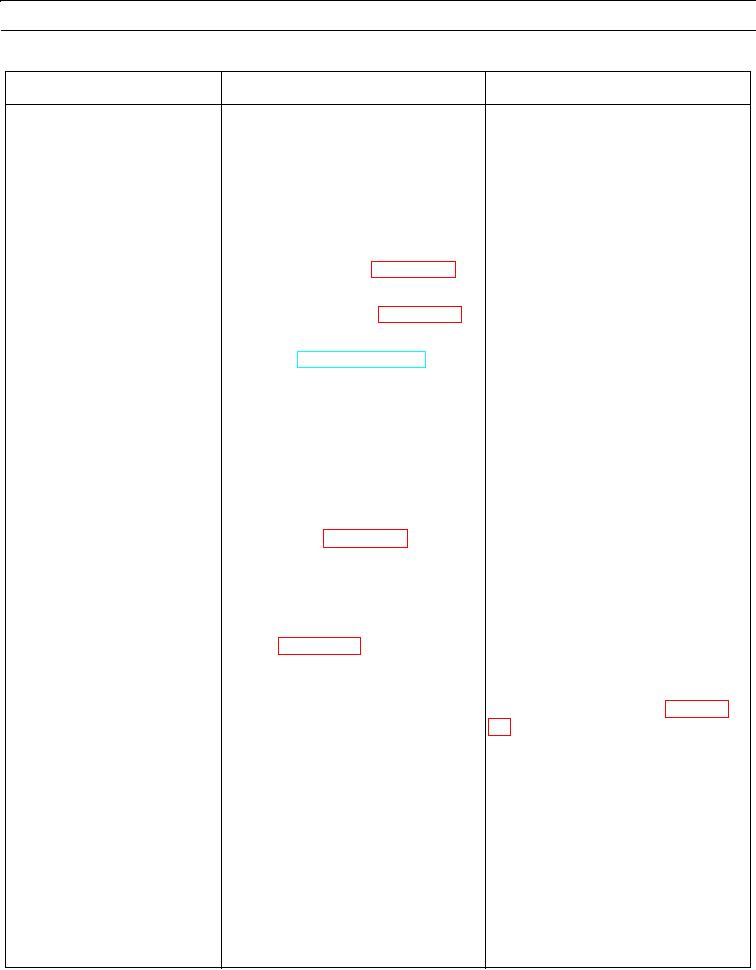

Table 1. Engine Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. If solidified fuel is found, drain and fill

7. If temperature is below 32oF (0oC),

18. Intermittent Low Power or

tank (WP 0166 00).

Power Cutout - Continued.

check for solidified fuel (wax) if tank.

2. If problem still exists, go to Test 8.

8. With engine shutdown, connect MSD 1. If no faults are found, go to Test 10.

and verify boost pressure is 0 psi (0

2. If either of these diagnostic codes are

kPa) and 102-03 Boost Pressure Sensor

logged, go to Test 9.

Short to Batt or 102-04 Boost Pressure

Sensor Short to Ground diagnostic

codes are not active (WP 0006 00).

9. Perform Engine Pressure Sensor Open If problem still exists, go to Test 10.

or Short Circuit Test (WP 0013 00).

10. Check restriction indicator on air

1. If restriction is indicated, clean or

cleaner (TM 5-3805-290-10).

replace air cleaner elements (WP 0032

00), remove any blockages or

restrictions, and replace damaged air

inlet and exhaust system lines or hoses

(WP 0033 00 and WP 0041 00).

2. If problem still exists, go to Test 11.

11. Verify that J1/P1 connector is correctly 1. If necessary, reconnect J1/P1.

connected.

2. If problem still exists, go to Test 12.

12. Perform Electrical Power Supply

If problem still exists, go to Test 13.

Circuit Test (WP 0013 00).

13. Verify fuel injection pump electrical

1. If necessary, reconnect fuel injection

connector is correctly connected (WP

pump connector.

0164 00).

2. If problem still exists, go to Test 14.

14. Perform Fuel Injection Pump Circuit

If problem still exists, go to Test 15.

Test (WP 0013 00).

15. Operate engine at maximum no-load

If percentages are not within

speed. If programmed upper demand

specifications, perform Digital Throttle

limit cannot be obtained, check throttle

Position Sensor Circuit Test (WP 0013

position to ensure it is within

calibration (80 to 87%) at high idle. If

engine speed is erratic, reduce engine

speed. Check that low idle position is

within calibration (20 to 27%) at low

idle. Slowly increase engine speed.

Check that engine speed is steady.

Check that position increases with

more throttle.

0008 00-15