TM 5-3805-290-23-1

TROUBLESHOOTING WITHOUT A DIAGNOSTIC CODE - CONTINUED

0008 00

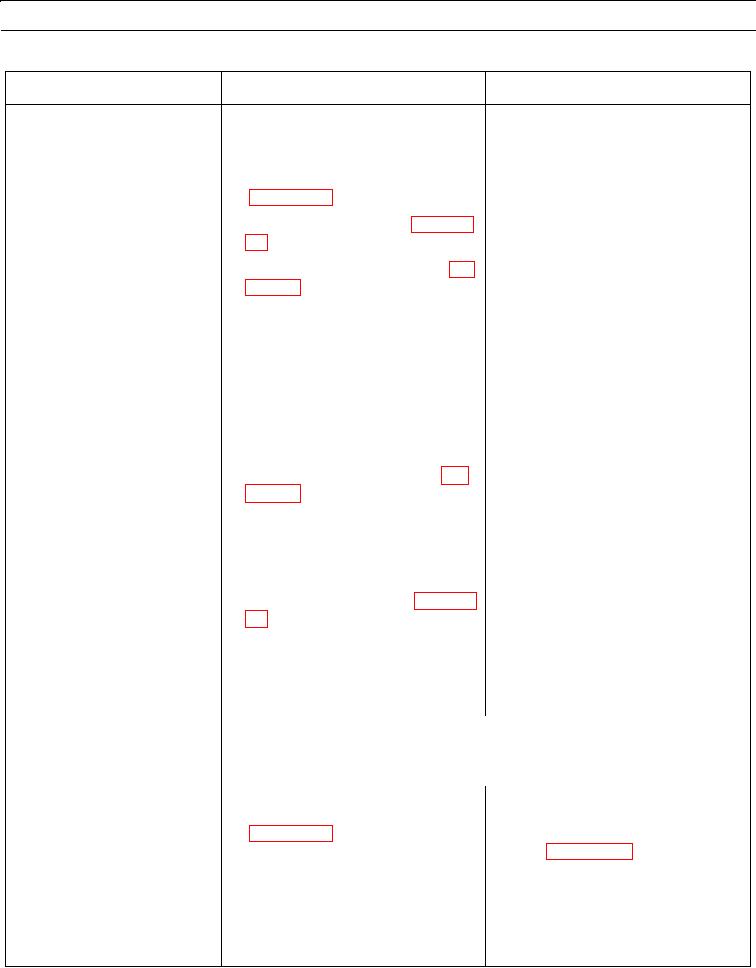

Table 1. Engine Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. Visually check fuel tank for fuel (fuel

1. Add fuel if necessary (TM 5-3805-290-

16. Poor Acceleration or

gage may be faulty).

10).

Response - Continued.

2. If problem still exists, go to Test 3.

3. Perform Fuel System Pressure Test

If problem still exists, go to Test 4.

4. Perform Fuel Quality Test (WP 0011

If problem still exists, go to Test 5.

5. Perform Air in Fuel System Test (WP

If problem still exists, go to Test 6.

6. Check for fuel supply lines that are

1. Replace or repair any restricted fuel

restricted.

lines (WP 0030 00, WP 0035 00, and

WP 0038 00) and replace fuel filters

(WP 0036 00).

2. If problem still exists, go to Test 7.

1. If solidified fuel is found, drain and fill

7. If temperature is below 32oF (0oC),

tank (WP 0166 00).

check for solidified fuel (wax) in tank.

2. If problem still exists, go to Test 8.

8. Perform Cylinder Balance Test (WP

1. If there is no reduction in engine speed,

go to Test 12.

2. If there is a reduction in engine speed,

go to Test 9.

9. Check valve lash (WP 0155 00).

1. If necessary, adjust valve lash.

2. If problem still exists, go to Test 10.

10. Perform Compression Test (WP 0010

1. If compression is low on one or more

cylinders, replace engine (WP 0145

00).

2. If compression is OK, go to Test 11.

11. Check fuel injection nozzles (WP 0163 If damaged, replace fuel injection

nozzle(s).

00).

CAU T I ON

17. Low Power/Poor or No

Response to Throttle.

DO NOT crank engine continuously for more than 30 seconds. Allow start-

ing motor to cool for two minutes before cranking engine again.

1. Connect MSD and check for active

1. Troubleshoot any active codes before

diagnostic codes using ET software

continuing with this procedure. Refer

to Troubleshooting With a Diagnostic

Code (WP 0009 00).

2. If problem still exists, go to Test 2.

2. Inspect engine oil level (TM 5-3805-

1. If necessary, add oil (TM 5-3805-290-

290-10).

10).

2. If problem still exists, go to Test 3.