TM 5-3805-290-23-1

TROUBLESHOOTING WITHOUT A DIAGNOSTIC CODE - CONTINUED

0008 00

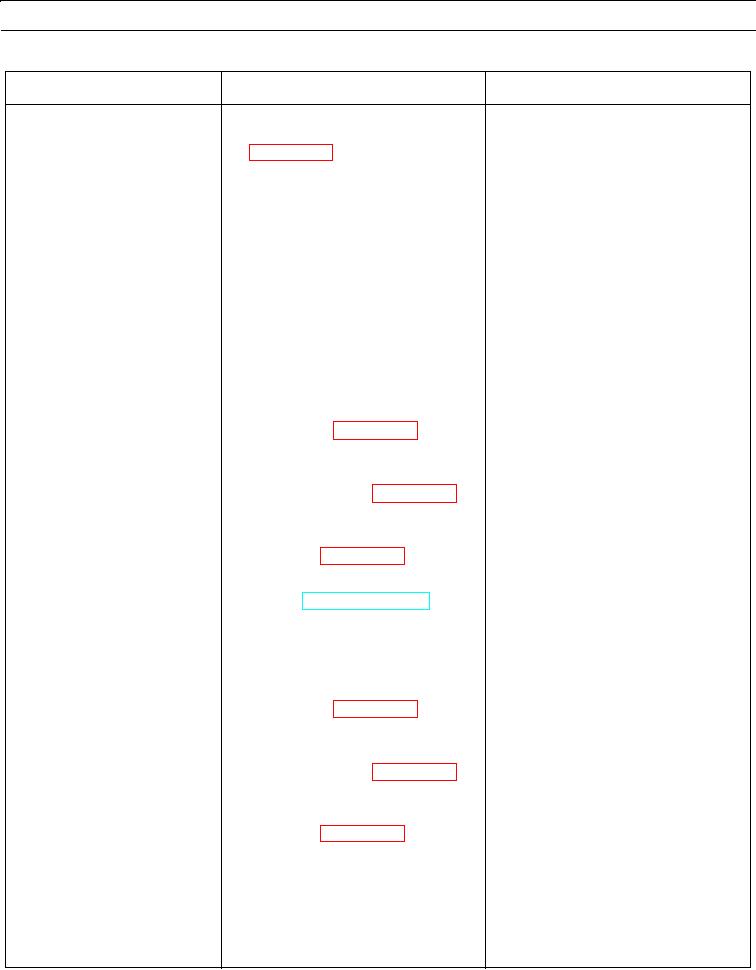

Table 7. Hydraulic System Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Ensure engine is operating correctly.

If problem still exists, go to Test 2.

1.

Hydraulic Power is Low.

Perform Torque Converter Stall Test

2. Check hydraulic oil level (TM 5-3805- 1. Add oil if necessary.

290-10).

2. If problem still exists, go to Test 3.

3. Check hydraulic system for leaks.

1. Repair any leaks (WP 0131 00 thru WP

0136 00).

2. If problem still exists, go to Test 4.

4. Check oil temperature.

If oil temperature is too high, refer to

Malfunction 10, Oil Temperature is Too

High in this work package.

5. Check for air bubbles in oil.

If air bubbles are present, refer to

Malfunction 11, There Are Air Bubbles in

Oil in this work package.

6. Perform Pilot System Pressure

If problem still exists, go to Test 7.

Pressure Test (WP 0017 00).

7. Check high pressure cutoff of

If problem still exists, go to Test 8.

implement pump. Perform Piston

Pump Pressure Test (WP 0016 00).

8. Check line relief valves setting.

If problem still exists, replace pilot

Perform Relief Valve (Line) Test and

operated control (WP 0188 00).

Adjustment (WP 0017 00).

1. Ensure lockout switch is in OFF

If problem still exists, go to Test 2.

2.

No Functions Will Operate

position (TM 5-3805-290-10).

or All Functions Operate

Slowly.

2. Visually inspect hydraulic system for

1. Repair any leaks found.

leaks in system.

2. If problem still exists, go to Test 3.

3. Perform Pilot System Pressure

If problem still exists, go to Test 4.

Pressure Test (WP 0017 00).

4. Check high pressure cutoff of

If problem still exists, go to Test 5.

implement pump. Perform Piston

Pump Pressure Test (WP 0016 00).

5. Check standby pressure. Refer to

1. If standby pressure cannot be adjusted,

Piston Pump Pressure Test and

refer to Malfunction 5, Standby

Adjustment (WP 0017 00).

Pressure Cannot be Adjusted Correctly

in this work package.

2. If problem still exists, go to Test 6.