TM 5-3805-290-23-1

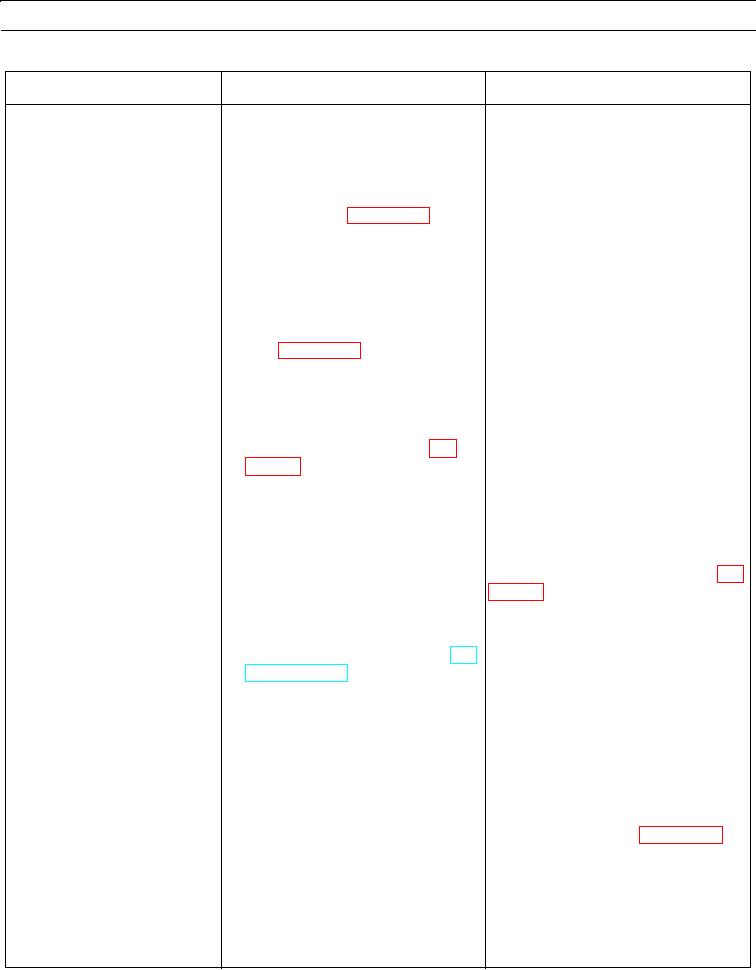

TROUBLESHOOTING WITHOUT A DIAGNOSTIC CODE - CONTINUED

0008 00

Table 7. Hydraulic System Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

6. Drain hydraulic tank (WP 0137 00) and 1. Clean screen or replace pump as

2.

No Functions Will Operate

necessary.

inspect inlet screen on implement

or All functions Operate

pump for contamination (WP 0182 00). 2. If problem still exists, go to Test 7.

Slowly - Continued.

7. Check signal limiter valve adjustment.

1. Adjust signal limiter valve if necessary.

Refer to Piston Pump Pressure Test

2. If problem still exists, replace pilot

and Adjustment (WP 0017 00).

operated control (WP 0188 00).

3. If problem still exists, replace main

control valve (WP 0189 00).

4. If problem still exists, replace cylinders

(WP 0128 00 and WP 0129 00).

1. Check setting for pressure reducing

1. Adjust as necessary.

3.

Pilot Oil Pressure is Low.

valve. Refer to Pilot System Pressure

2. If problem still exists, go to Test 2.

Test (WP 0017 00).

2. Steering pump pressure for low

If problem still exists, go to Test 3.

pressure standby pressure is not

correct. Perform Piston Pump

(Steering and Pilot Oil) Low Pressure

Standby Test and Adjustment (WP

3. Signal drain valve is not functioning

1. Replace main control valve (WP 0189

correctly.

00).

2. If problem still exists, go to test 4.

4. Pressure reducing valve is

Loosen adjusting screw on pressure

reducing valve and turn screw inward (WP

contaminated.

1. Check hydraulic oil for correct oil

1. Add or change oil if necessary (WP

4.

Piston Pump for Work

0121 00).

viscosity or grade (WP 0019 00),

Tools Will Not Reach High

2. If problem still exists, go to Test 2.

contamination, and correct level (TM

Pressure Cutoff.

2. Check for air in oil.

1. If air is present, refer to Malfunction

11, There Are Air Bubbles in Oil in this

work package.

2. If problem still exists, go to Test 3.

3. Cutoff spool is stuck.

1. Loosen cutoff spool adjusting screw

and attempt to readjust high pressure

cutoff. Refer to Piston Pump Pressure

Test and Adjustment (WP 0017 00).

2. If problem still exists, replace main

control valve (WP 0189 00).

3. If problem still exists, replace

implement pump (WP 0182 00).

Spring or margin spool is damaged.

If problem still exists, replace implement

5.

Standby Pressure Cannot

pump (WP 0182 00).

be Adjusted Correctly.