TM 5-3805-290-23-1

TROUBLESHOOTING WITH A DIAGNOSTIC CODE - CONTINUED

0009 00

Table 2. Machine Control System - Continued.

(MID 081)

TEST OR INSPECTION

CORRECTIVE ACTION

CID FMI CODE

1251 00

427-B1879

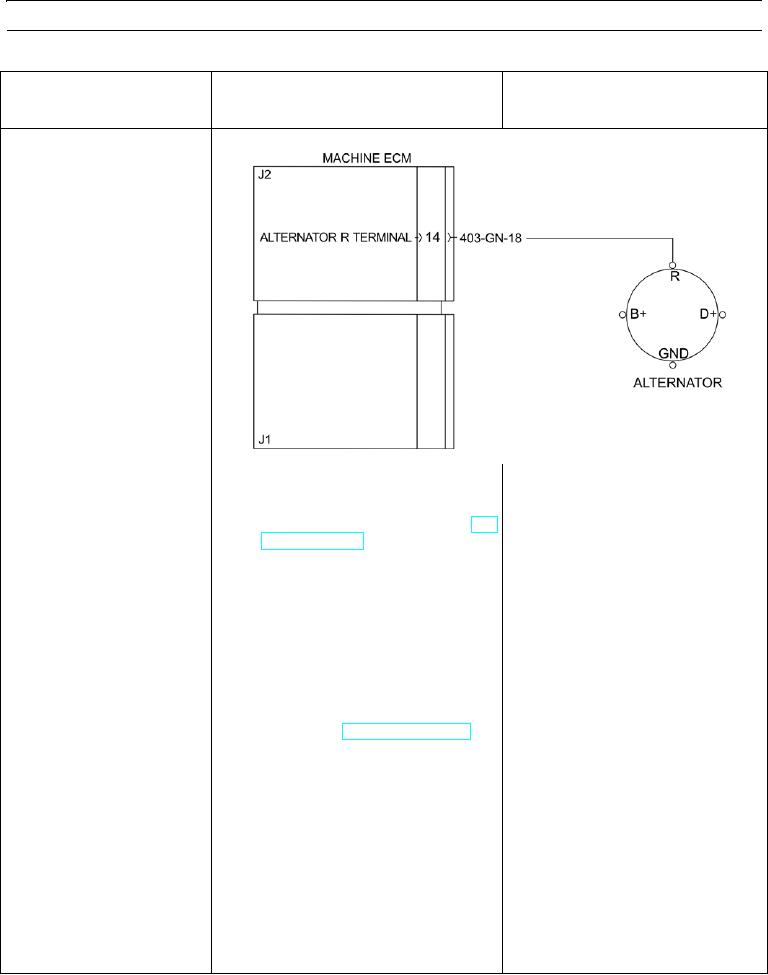

1. If resistance is greater than 5,000

1. Check R-terminal circuit for a short to

Ohms, go to Test 2.

+battery.

2. If resistance is less than 5.0 Ohms,

(a) Turn engine start switch and battery

there is a short to +battery. Replace

disconnect switch to OFF position (TM

wire in circuit for R-terminal, or repair

circuit (WP 0079 00).

(b) Disconnect J1 and J2 harness

connectors from machine ECM (WP

0052 00).

(c) Measure resistance from alternator R-

terminal wire (403 GN 18) to all

contacts used in J1 and J2 harness

connectors.

1. If alternator R-terminal is an 11 to 32V

2. Check machine alternator.

square-wave from 0 to 2 KHz, go to

(a) Disconnect wire (403 GN 18) from

Test 3.

2. If alternator R-terminal is not an 11 to

(b) Start engine (TM 5-3805-290-10).

32V square-wave from 0 to 2 KHz,

(c) Measure alternator R-terminal to verify

replace alternator (WP 0047 00).

there is 11 to 32V square-wave from 0

to 2 KHz. There should not be a steady

dc voltage equivalent to battery

present.