TM 5-3805-290-23-1

FUEL SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0011 00

FUEL SYSTEM PRESSURE TEST

0011 00

N OT E

Pressure test measures output pressure of fuel transfer pump. Low fuel pressure and starting difficulty

may be indications of problems with fuel transfer pump.

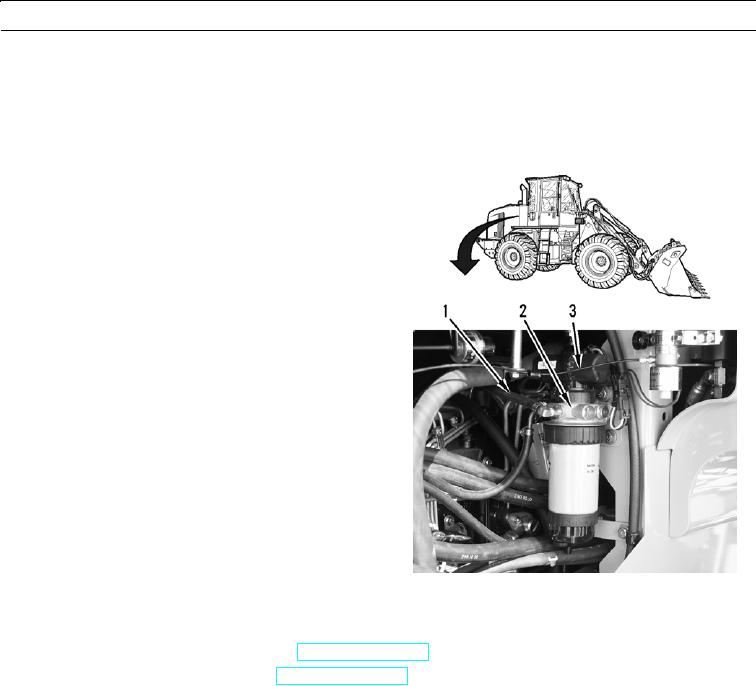

Fuel transfer pump is located on left side of machine at top of primary fuel filter.

1.

Disconnect hose (1) from fuel outlet port at base of

primary fuel filter (2).

2.

Install fuel pressure gage to fuel outlet port.

427-B0654

3.

Prime fuel system (WP 0029 00), to eliminate air from fuel transfer pump.

4.

Position fuel shutoff lever in OFF position. (TM 5-3805-290-10).

5.

Turn engine start switch to ON position (TM 5-3805-290-10). Record maximum pressure. Pressure indication on gage

should be 10 psi (67 kPa).

6.

If pressure is less than minimum pressure, replace fuel transfer pump (3) (WP 0031 00).

7.

Observe rate at which pressure drops. If pressure drops to one-half of maximum pressure in less than 30 seconds,

replace fuel transfer pump (3) (WP 0031 00).

8.

Remove pressure gage from fuel outlet port. Connect hose (1) to fuel outlet port. Prime fuel system to eliminate air from

fuel system (WP 0029 00).