TM 5-3805-290-23-1

FUEL SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0011 00

FUEL INJECTION TIMING CHECK - CONTINUED

9.

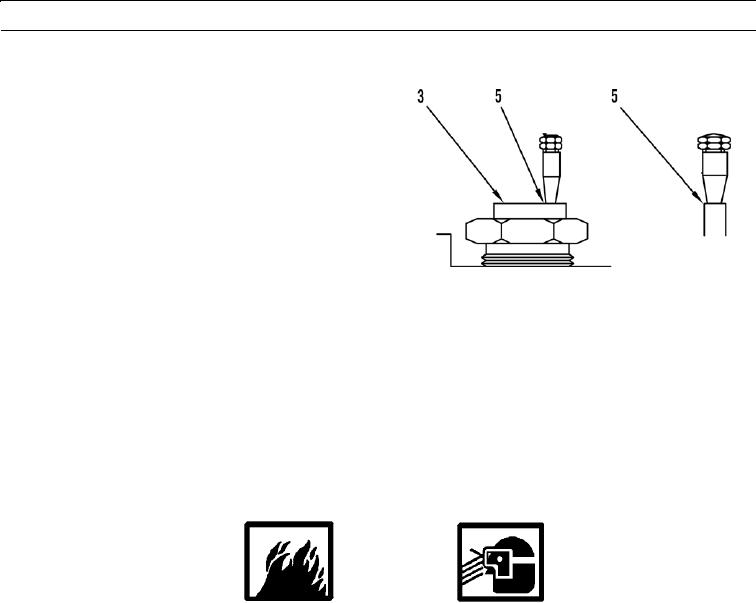

Rotate crankshaft in direction of engine rotation until

machined face at top of probe (5) aligns with top of

main body (3). No. 1 piston is now at four degrees

after top-center on compression stroke.

427-B0653

N OT E

When step is complete, DO NOT rotate crankshaft until fuel injection pump is to be installed on engine.

10.

Remove probe (5) from main body (3).

11.

Remove gland nut (4).

12.

Remove main body (3) from cylinder head.

13.

Install fuel injector nozzle (WP 0163 00).

CYLINDER BALANCE TEST

0011 00

11

11

WARN I N G

DO NOT perform fuel system checks, inspections or maintenance while smoking or near fire, flames, or

sparks. Fuel may ignite, causing injury or death to personnel or damage to machine.

Operating personnel must wear fuel-resistant gloves when handling fuels. If exposed to fuel, promptly wash

exposed skin and change fuel-soaked clothing. Failure to follow this warning may result in injury to personnel.

Eye protection must be worn when performing this test procedure. Failure to take precautions could cause

injury to personnel.

11

CAU T I ON

Use caution to ensure fuel system does not become contaminated. Keep work area clean. Contamina-

tion of fuel system could result in premature failure.

Use two line wrenches for removal of injector lines to avoid damage to fittings and connectors.

N OT E

Use a container to catch any fuel that may drain from system. Dispose of fuel IAW local policy and

ordinances. Ensure all spills are cleaned up.

This on-vehicle test can be performed to find cylinder that is misfiring and causing erratic engine idle

and black smoke.

1.

While running engine at low idle, loosen fuel line nut at fuel injector nozzle. This will stop flow of fuel to that cylinder.