TM 5-3805-290-23-1

TRANSMISSION TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0014 00

TRANSMISSION CONTROL (SHIFT LEVER) TEST - CONTINUED

10.

Check ECM.

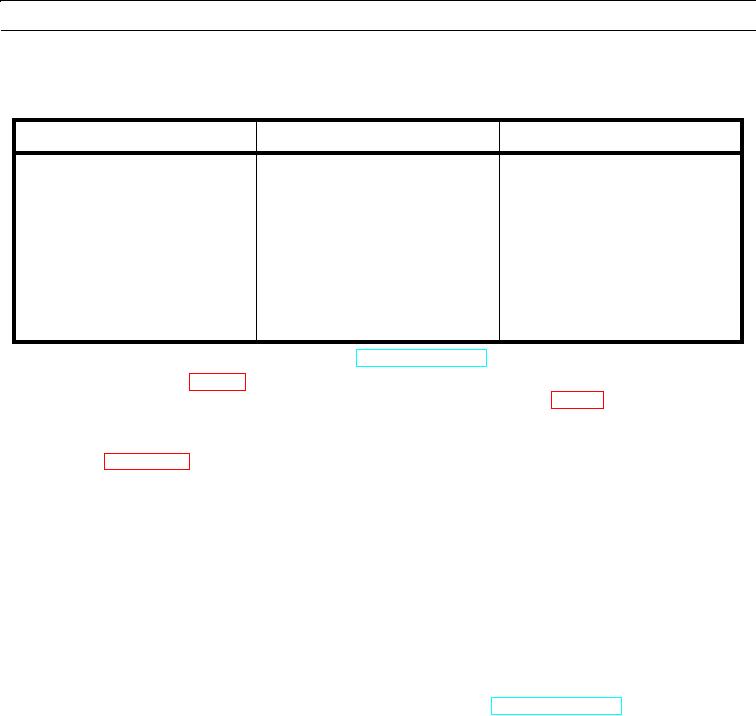

Table 4. Machine ECM Connector Pin Assignments.

Function

Wire Assignment

Machine ECM Pin Assignments

Forward

G750-BU

Connector J2, Pin 49

Neutral

G763-PU

Connector J2, Pin 23

Reverse

G755-GY

Connector J2, Pin 28

First Gear

G768-GN

Connector J2, Pin 50

Second Gear

G760-WH

Connector J1, Pin 41

Third Gear

G761-YL

Connector J1, Pin 42

Fourth Gear

G762-BR

Connector J1, Pin 43

a.

Turn battery disconnect switch to OFF position (TM 5-3805-290-10).

b.

Using information in Table 4, remove corresponding wires from machine ECM harness connectors J1 and J2.

Also, use shifter schematic for reference. After removing all wires shown in Table 4, momentarily connect to

frame ground individually. Ensure wires cannot accidentally touch frame ground.

c.

Turn service disconnect switch to ON position. Start machine with key in RUN position, and connect and start up

MSD (WP 0006 00).

d.

Select powertrain ECM and go to status screen 4.

e.

Monitor status of shifter on MSD screen.

f.

Expected Results. As each combination of contacts is grounded, MSD screen displays corresponding shifter posi-

tion.

(1)

If results are OK, ECM is working properly. Wiring harness may have failed. Replace wiring harness in

question (WP 0169 00 thru WP 0175 00).

(2)

If results are NOT OK, ECM may have failed. Clean contacts for ECM harness connectors. It is unlikely

that ECM has failed. Exit this procedure and perform entire procedure again. If problem remains, replace

ECM. It is preferable to show new ECM corrects problem and suspect ECM demonstrates problem.

11.

Verify shift lever remote F/N/R switch functionality.

a.

Place shift lever on steering column in NEUTRAL and FIRST GEAR (TM 5-3805-290-10).

b.

At shifter 4-pin connector, remove jumper wire between pin 3 and pin 4.

c.

Connect 4-pin receptacle connector CN-C50 from cab harness to shifter 4-pin plug (WP 0081 00). This will enable

remote F/N/R switch circuit for shift lever.

d.

Ensure pins and sockets are seated properly and connector mates correctly.

e.

Place remote F/N/R switch in FORWARD position.

f.

Verify MSD shows "F1" as desired gear.

g.

Place remote F/N/R switch in REVERSE position.

h.

Verify MSD shows "R1" as desired gear.

i.

Expected Results. As each combination is switched, MSD screen displays corresponding gear and direction.

(1)

If status of shift lever position changes properly, monitor machine to check if problem occurs. If problem

occurs, repeat entire test procedure.

0014 00-15